Unlocking Efficiency: How Industrial CNC Machines Revolutionize Manufacturing Processes Today

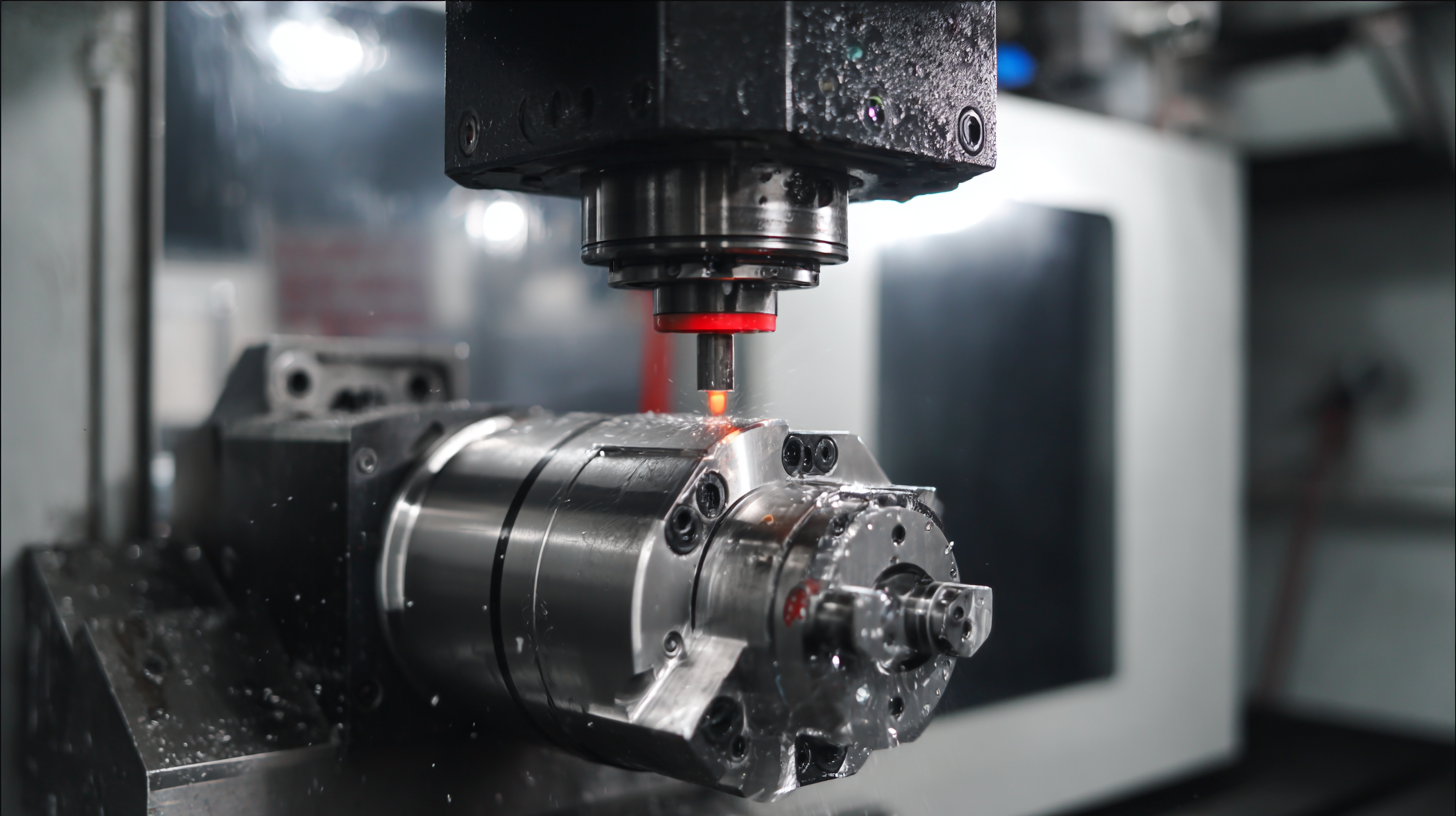

In today's fast-paced manufacturing landscape, the integration of advanced technology is paramount to achieving operational efficiency and competitive advantage. One such transformative innovation is the industrial CNC (Computer Numerical Control) machine, which has redefined production processes across various industries. By leveraging precise automation and advanced programming capabilities, industrial CNC machines enable manufacturers to produce complex components with unparalleled accuracy and speed.

This shift towards digitized manufacturing not only reduces waste and minimizes human error but also enhances flexibility in production, allowing for rapid adaptation to changing market demands. As industries continue to embrace this technological evolution, understanding the vital role that industrial CNC machines play in streamlining operations and driving productivity gains becomes essential for businesses aiming to thrive in an increasingly competitive environment.

The Role of CNC Machines in Enhancing Production Accuracy

The integration of CNC machines into modern manufacturing practices has heralded a new era of production accuracy. These advanced tools utilize computer-controlled processes that allow for repetitive precision, drastically reducing human error. According to industry reports, CNC machining can enhance productivity by up to 50%, making it a game-changer for manufacturers aiming for high efficiency. With the ongoing demand for customization and fast turnaround times, CNC technology has become indispensable across various sectors, from automotive to aerospace.

Tips for maximizing CNC efficiency include regular maintenance and calibration, which ensure that machines operate at optimal performance levels. Additionally, investing in training for operators can lead to a better understanding of machine capabilities and limitations, further enhancing production accuracy. As companies increasingly shift from traditional methods to automated solutions, embracing these practices can significantly impact profitability and product quality.

Furthermore, the eco-friendly capabilities of modern CNC machines cannot be overlooked. These machines are designed to minimize waste and energy consumption, supporting sustainability initiatives while also enabling manufacturers to transition smoothly towards more environmentally responsible operations. By aligning production methods with both efficiency and ecological considerations, businesses can stay competitive in a rapidly evolving market.

Unlocking Efficiency: How Industrial CNC Machines Revolutionize Manufacturing Processes Today

| Feature | Description | Impact on Production | Accuracy Improvement (%) |

|---|---|---|---|

| Precision Cutting | CNC machines provide highly precise cutting based on programmable parameters. | Reduces material waste and improves product dimensional accuracy. | 25% |

| Automated Operations | CNC machines can operate with minimal human intervention, enhancing workflow. | Increases throughput and reduces labor costs. | 30% |

| Complex Geometries | CNC machining can produce complex shapes that are difficult with traditional methods. | Allows for innovative product designs and decreases the need for assembly. | 40% |

| Rapid Prototyping | Faster turnaround times for prototypes allow for quick testing and adjustments. | Shortens development cycles significantly. | 50% |

| Consistency | CNC machines maintain high levels of consistency across production runs. | Minimizes variations between products, enhancing quality assurance. | 35% |

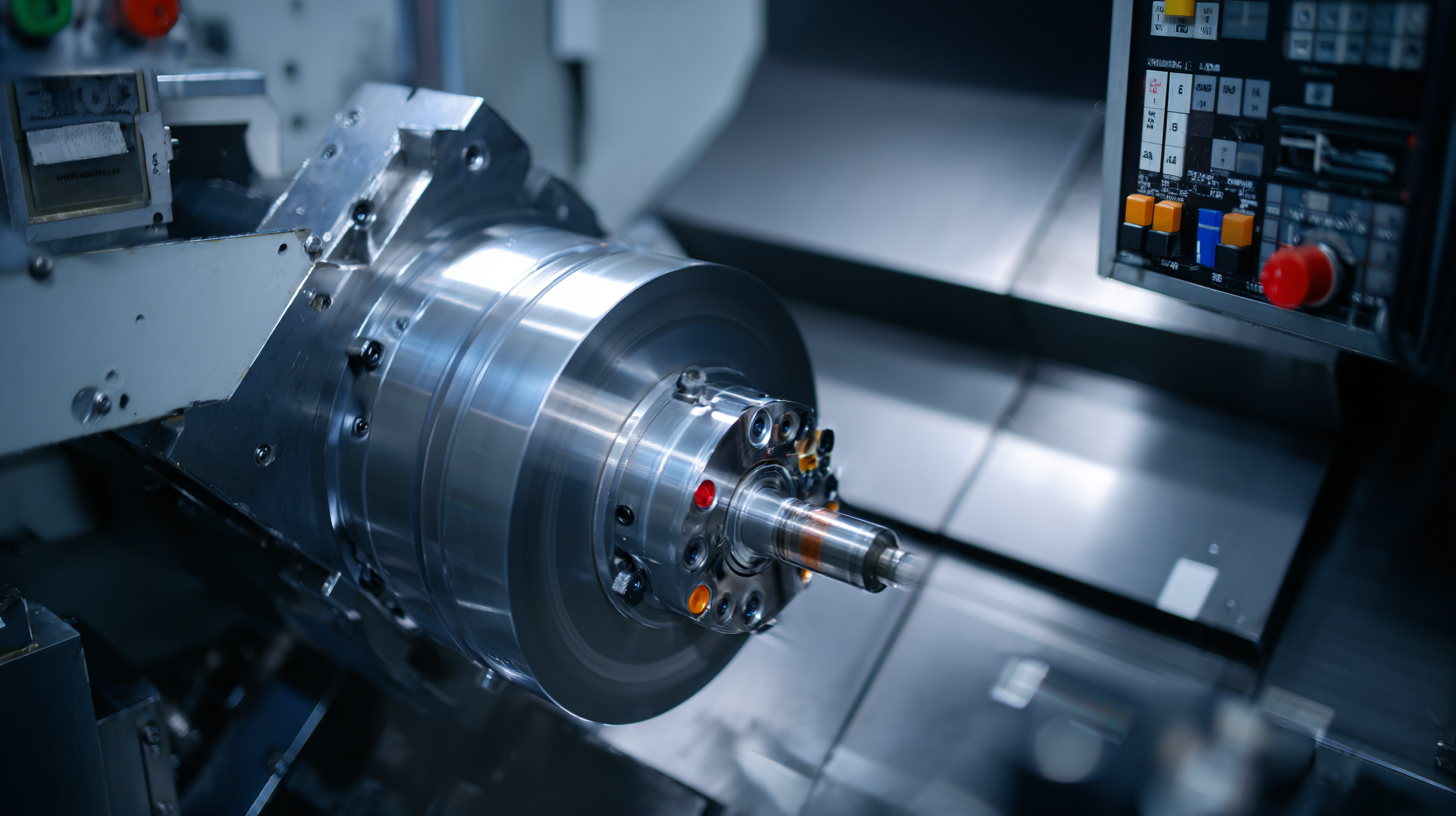

Integrating Automation: Streamlining Workflow with CNC Technology

The integration of automation through CNC (Computer Numerical Control) technology has significantly transformed manufacturing workflows, making them more efficient and effective. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach USD 117.2 billion by 2025, growing at a CAGR of 6.2%. This growth is largely driven by the need for precision engineering and the ability to produce complex components with minimal human intervention.

Automated CNC machines streamline operations by reducing manual errors and the time taken for production. A study by McKinsey & Company highlights that implementing automation in manufacturing can increase productivity by up to 30%. This efficiency stems from the machines’ ability to continuously operate with high accuracy, decreasing downtime and waste. Additionally, as industries increasingly adopt Industry 4.0 principles, integrating CNC machines with IoT (Internet of Things) technology allows for real-time monitoring and predictive maintenance, further enhancing workflow efficiency and reducing costs.

Cost Efficiency: How CNC Machines Reduce Manufacturing Expenses

In today's fast-paced manufacturing environment, the utilization of CNC machines emerges as a game-changer in reducing operational costs. By automating intricate processes, these machines minimize human error and labor costs, leading to significant savings. Traditional manufacturing methods often require extensive manual labor and substantial time investment, resulting in higher production expenses. In contrast, CNC machines streamline workflows, allowing for increased precision and speed, which translates directly to lower costs.

**Tips**: To maximize cost efficiency while using CNC machines, ensure regular maintenance to prevent downtime. Additionally, investing in training for operators can lead to better programming and operational practices, ultimately enhancing productivity.

Furthermore, CNC technology enables manufacturers to produce parts and products with less material waste. The precise cutting capabilities of CNC machines ensure that raw materials are utilized effectively, reducing excess scrap that can inflate costs. By integrating CNC systems into the production line, businesses can achieve optimal resource management, enhancing their profit margins while meeting customer demands quickly and accurately.

**Tips**: Consider implementing software that optimizes material usage in your CNC operations. This not only helps in minimizing waste but also improves overall efficiency.

Cost Efficiency of CNC Machines in Manufacturing

Customization and Flexibility: Tailoring Production with CNC Systems

In today’s rapidly evolving manufacturing landscape, CNC (Computer Numerical Control) systems stand out for their remarkable capacity for customization and flexibility. As the Industry 4.0 wave sweeps through, manufacturers are increasingly turning to CNC technology, which allows for the precise and efficient production of varied components tailored to specific client needs. According to a report by Allied Market Research, the global CNC machine market is expected to reach $117.51 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.39% from 2019 to 2026. This growth can largely be attributed to the machines' ability to adapt quickly to different production requirements, reducing lead times and accommodating small batch sizes.

One of the standout features of CNC systems is their ability to integrate advanced software that enables rapid design changes. This adaptability not only streamlines the production process but also enhances product personalization—allowing businesses to offer customized solutions with minimal downtime. Research from the Marketers' Insights Group suggests that 74% of manufacturers are already leveraging CNC technology to enhance their production flexibility, while 63% report improved operational efficiency as a result. The capacity for customization through CNC systems empowers manufacturers to remain competitive in an ever-dynamic marketplace, catering to a diverse clientele while maintaining high-quality standards.

Future Trends in CNC Technology: Innovations Shaping Manufacturing Tomorrow

The adoption of advanced CNC technologies is transforming the landscape of manufacturing, paving the way for a future defined by innovation and efficiency. According to recent market analysis, the global CNC controller market, valued at $3.2 billion in 2023, is projected to soar to $7.2 billion by 2033, reflecting a compound annual growth rate (CAGR) of 8.3% from 2024 onwards. This growth is indicative of the increasing demand for automation and precision in manufacturing processes across various industries.

Emerging trends such as AI integration and modular designs are shaping the future of industrial machine design. The CNC machine tools market is expected to grow by USD 21.9 billion between 2025 and 2029, propelled by the rising demand for high-precision and multi-axis machining centers. Innovations in CNC technology are not only enhancing productivity but also offering unprecedented flexibility, allowing manufacturers to adapt swiftly to changing market conditions and consumer demands. As these technologies continue to evolve, they will undoubtedly revolutionize manufacturing processes altogether.

Related Posts

-

7 Best Industrial CNC Machines Revolutionizing Precision Manufacturing Today

-

Understanding the Benefits of Table CNC Machines for Modern Manufacturing

-

Digital Strategies for Enhancing CNC Cutting Efficiency

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success

-

Understanding the Specifications of the Best Industrial CNC Plasma Table and How to Use It

-

7 Best HD Plasma Cutters for Precision Metal Cutting in 2023