Solutions for Optimizing Your Workflow with the Best Small CNC Plasma Cutting Machines

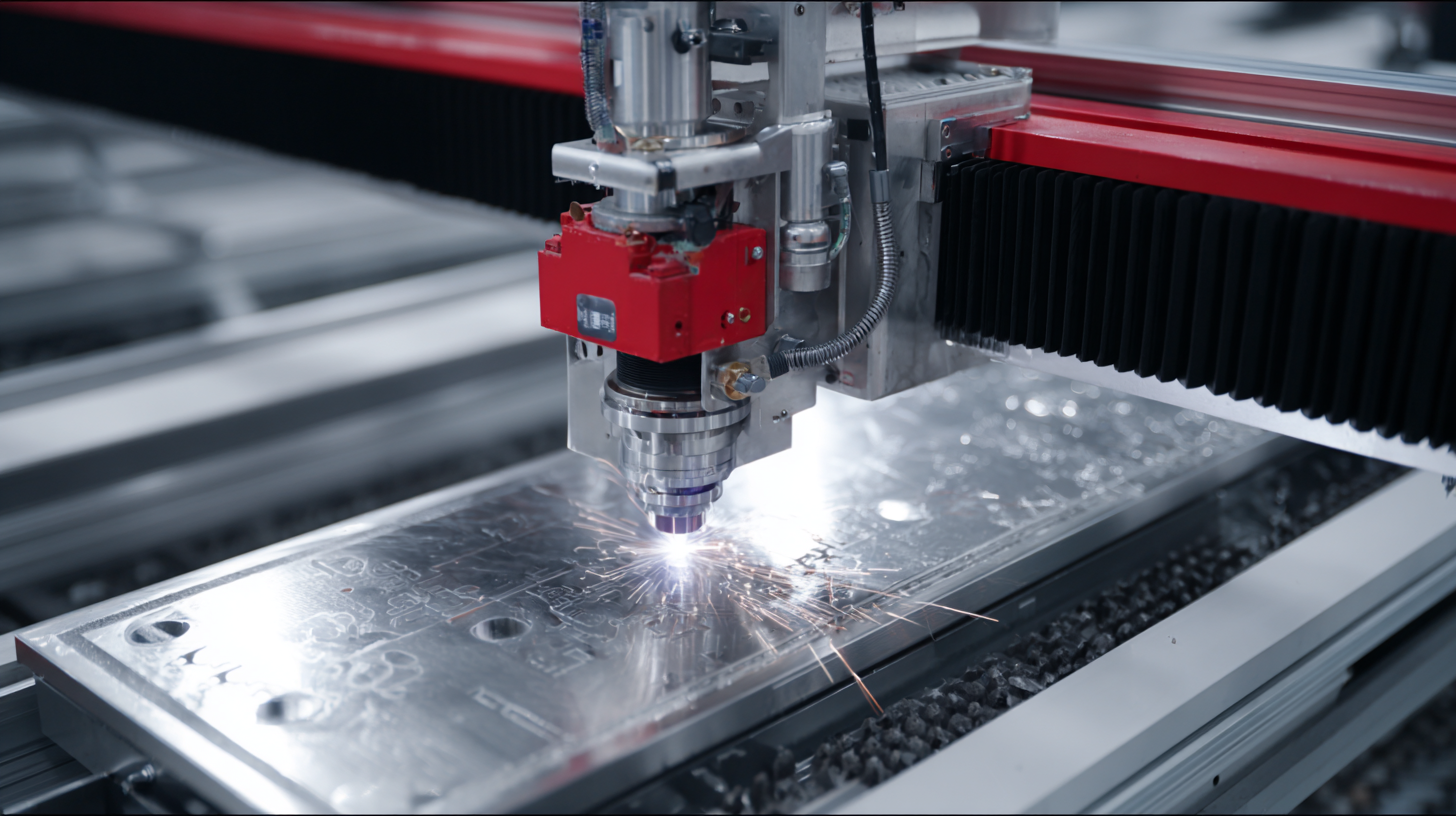

In the fast-evolving landscape of manufacturing, the demand for efficiency and precision has never been higher. According to a recent market report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.24 billion by 2025, fueled by advancements in automation and the need for high-quality fabrication. Among these advancements, small CNC plasma cutting machines have emerged as a game-changer for small to medium-sized enterprises seeking to optimize their workflows. These machines not only offer remarkable speed and precision in cutting a variety of materials but also provide a cost-effective solution for businesses aiming to enhance productivity. As we navigate the "Industry 2025 Technology Trends," integrating small CNC plasma cutting machines into manufacturing processes is crucial for staying competitive in an increasingly automated world, where customization and efficiency are paramount.

Benefits of Small CNC Plasma Cutting Machines for Small Businesses

Small CNC plasma cutting machines are revolutionizing the operational capabilities of small businesses. These machines provide precise cutting solutions that are not only efficient but also cost-effective, making them ideal for startups and smaller enterprises looking to establish a foothold in competitive markets. With the CNC plasma cutting machine market projected to grow significantly—estimated at USD 673.2 million by 2024 and continuing to expand—it's clear that these machines play a crucial role in modern manufacturing environments.

Tips for maximizing your workflow with small CNC plasma cutting machines include investing in training for your staff to optimize machine usage, which can drastically improve efficiency. Additionally, integrating software that allows for streamlined design-to-production processes can further enhance output, ensuring that your team is never slowing down. Regular maintenance of your machines is also essential; this not only prolongs the lifespan of your equipment but also minimizes downtime, which can be critical for meeting customer demands.

Moreover, considering the rising demand for desktop CNC machines, small businesses can expand their service offerings by incorporating varied cutting capabilities. By diversifying their operations, they can attract a broader client base and increase profitability. Embracing these technologies and strategies positions small businesses for sustained growth in the evolving landscape of manufacturing.

Key Features to Look for in Top Small CNC Plasma Cutters

When selecting the best small CNC plasma cutting machines, key features play a pivotal role in optimizing your workflow. One of the primary aspects to consider is the cutting thickness capacity. A versatile machine that can handle various materials, such as steel, aluminum, and stainless steel, significantly enhances productivity. Additionally, look for models equipped with advanced torch height control systems, as these ensure consistent cutting quality across different material thicknesses and improve overall accuracy.

Another critical feature is the software compatibility of the machine. Modern CNC plasma cutters should come with user-friendly software that supports various design formats, enabling seamless integration with your existing workflows. Features like easy-to-navigate interfaces, built-in design tools, and the ability to import files from CAD programs streamline the setup process. Additionally, consider the machine's speed and precision, as a faster cutting speed without compromising accuracy can drastically reduce production times and increase efficiency. By focusing on these essential features, you can enhance your cutting tasks and maximize the potential of your small CNC plasma cutter.

Comparative Analysis: Efficiency and Speed of Small CNC Plasma Machines

As the landscape of advanced manufacturing continues to evolve, the comparative efficiency and speed of small CNC plasma cutting machines have become critical factors in optimizing workflows. Recent studies indicate that these machines can achieve cutting speeds of up to 60 inches per minute, significantly reducing production time compared to traditional cutting methods. Furthermore, advancements in cold plasma technology have shown promise in enhancing precision and reducing material waste, making them invaluable for industries that depend on rapid turnaround and high-quality finishes.

Tip: When selecting a small CNC plasma machine, consider looking for models equipped with adaptive cutting technology, which automatically adjusts settings based on material type and thickness. This feature not only increases efficiency but also ensures a cleaner cut, further optimizing your production workflow.

As industries worldwide, including those in China, are rapidly innovating in advanced techniques, staying abreast of these developments can give companies a competitive edge. Reports suggest that firms incorporating small CNC plasma systems are seeing an increase in overall productivity, with improvements not only in speed but also in the quality of their outputs.

Tip: Regular maintenance and software updates on your CNC plasma machine can significantly extend its lifespan and maintain cutting performance, allowing you to leverage the full potential of your investment.

Cost-Effectiveness: Analyzing the ROI of Investing in CNC Technology

Investing in CNC technology, particularly small CNC plasma cutting machines, can significantly improve the cost-effectiveness of your operations. The growing trend towards automation presents an opportunity for small and medium enterprises (SMEs) to enhance their productivity while reducing labor costs. In recent discussions on the benefits of collaborative robots, it’s clear that automation helps remove traditional barriers, allowing SMEs to optimize their workflows and achieve quicker return on investment (ROI). As these technologies evolve, businesses can measure costs and benefits on a more dynamic scale, focusing on productivity gains rather than just initial expenditures.

Moreover, recent forecasts indicate that automation will become an integral part of manufacturing processes, with industries increasingly adopting advanced technologies to streamline operations. Companies are finding that methods for measuring ROI on new equipment—including CNC machines—are evolving. Rather than relying solely on direct financial returns, businesses are now considering the long-term savings generated through increased efficiency and reduced operational costs. Ultimately, organizations that embrace CNC technology not only enhance their production capabilities but also position themselves for sustained growth and infrastructure resilience in the competitive market.

Solutions for Optimizing Your Workflow with the Best Small CNC Plasma Cutting Machines - Cost-Effectiveness: Analyzing the ROI of Investing in CNC Technology

| Machine Model | Initial Investment ($) | Annual Maintenance ($) | Average Hourly Rate ($) | Production Efficiency (units/hour) | ROI (%) |

|---|---|---|---|---|---|

| Model A | $15,000 | $500 | $75 | 10 | 200% |

| Model B | $18,000 | $600 | $80 | 12 | 180% |

| Model C | $20,000 | $700 | $90 | 15 | 220% |

| Model D | $25,000 | $800 | $100 | 18 | 250% |

Industry Trends: Growing Adoption of CNC Plasma Cutting in Various Sectors

The adoption of CNC plasma cutting technology is witnessing significant growth across various sectors, driven by a demand for enhanced precision and productivity in manufacturing processes. According to market analysis, the CNC machine market is projected to expand at a compound annual growth rate (CAGR) of 5.5% from 2025 to 2029, underscoring the increasing reliance on automated solutions in industrial operations. This trend reflects a broader shift towards smart manufacturing, where high-precision multi-axis machining centers are becoming essential for meeting the complex needs of modern fabrication.

Moreover, the sawing and cutting tools market, which was valued at USD 38.2 billion in 2025, is expected to grow substantially by 2035. This growth is fueled by a rising emphasis on efficiency and high-quality output in various applications, from automotive to aerospace industries. The integration of artificial intelligence (AI) within CNC technologies is also contributing to this transformation, enabling more sophisticated operational capabilities and further streamlining workflows. As businesses continue to seek innovative solutions, the embrace of CNC plasma cutting machines will likely remain a prominent trend in the manufacturing landscape.