How to Optimize Your Workflow with CNC Cutting Techniques

In the rapidly evolving manufacturing landscape, optimizing workflow has become paramount for companies seeking to enhance efficiency and productivity. CNC cutting, a method that utilizes computer numerical control technology, has emerged as a game-changer in this arena. According to a 2022 industry report by Mordor Intelligence, the global CNC cutting machine market is projected to reach $4.5 billion by 2027, growing at a CAGR of 5.1% from 2022. This growth underscores the increasing reliance on CNC cutting techniques for precision and speed in production processes. By implementing advanced CNC cutting methodologies, businesses can streamline their operations, reduce waste, and achieve higher levels of accuracy in their projects. This article will explore various strategies and best practices to help manufacturers optimize their workflows through the effective use of CNC cutting techniques.

Maximizing Efficiency: Key CNC Cutting Techniques to Streamline Your Production Process

Maximizing efficiency in your production process is crucial, and employing key CNC cutting techniques can significantly streamline workflows. One effective strategy is to implement advanced nesting software, which optimizes material usage by arranging the cutting patterns in a way that minimizes waste. This not only reduces the cost of raw materials but also enhances the speed of production, as machines work much more efficiently with better-planned layouts.

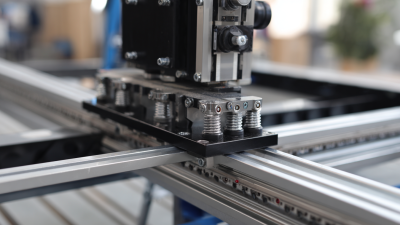

Another technique to consider is the use of high-speed machining and adaptive cutting strategies. These methods allow for faster cutting speeds and reduced cycle times while maintaining precision. By adjusting feed rates and cutting depth in real-time based on the material being processed, manufacturers can achieve a smoother workflow. Additionally, investing in automated tool changers can drastically cut downtime, ensuring that the CNC machines spend more time cutting and less on manual setup, ultimately boosting overall productivity.

Understanding the Role of Automated CNC Systems in Reducing Manufacturing Lead Times

The integration of automated CNC systems plays a pivotal role in reducing manufacturing lead times, ultimately enhancing workflow efficiency. According to a report from the International Federation of Robotics, the adoption of CNC technology in manufacturing has accelerated significantly, with over 2.7 million industrial robots in use worldwide by 2022. These automated systems not only streamline operations but also minimize errors associated with manual interventions, leading to a reduction in production delays.

Moreover, a study published by the Manufacturing Institute found that CNC systems can reduce lead times by up to 30%, translating to quicker turnaround for orders and increased responsiveness to market demands. This efficiency is further compounded by the software advancements that allow for real-time adjustments and optimizations. By leveraging these automated systems, manufacturers can achieve a more agile production environment, ensuring that they stay competitive in an increasingly fast-paced industry landscape.

How to Optimize Your Workflow with CNC Cutting Techniques

| CNC Technique | Material Type | Lead Time Reduction (%) | Cost Efficiency ($/Unit) | Application |

|---|---|---|---|---|

| Laser Cutting | Aluminum | 30% | 5.00 | Aerospace Components |

| Plasma Cutting | Steel | 25% | 8.00 | Construction |

| Waterjet Cutting | Glass | 15% | 12.00 | Interior Design |

| Router Cutting | Wood | 20% | 6.00 | Furniture |

| EDM Cutting | Titanium | 40% | 15.00 | Medical Equipment |

Choosing the Right Material: Impact of CNC Compatibility on Workflow Optimization

Choosing the right material for CNC cutting is crucial for optimizing your workflow. The compatibility of materials with CNC technology directly impacts the efficiency and quality of the final product. When selecting a material, consider factors such as density, hardness, and how well the material can withstand cutting pressures and speeds. Materials that are easier to machine will reduce wear on tools and minimize production time, thereby enhancing overall efficiency.

**Tips:**

1. **Research Material Properties:** Before finalizing a material, research its specific properties and how they relate to your project requirements. This can help you avoid costly mistakes and improve workflow.

2. **Test Runs:** Conduct small test runs using different materials to gauge which one performs best in your CNC setup. This experimentation can reveal unexpected advantages or issues.

3. **Utilize CAM Software:** Leverage the best CAM software available to optimize toolpaths and cutting parameters tailored to the selected material. This not only improves accuracy but also enhances your ability to manage production timelines effectively.

Impact of Material Choice on CNC Cutting Workflow Optimization

Integrating CAD/CAM Software: Enhancing CNC Cutting Accuracy and Reducing Errors

Integrating CAD/CAM software into CNC cutting processes significantly enhances

accuracy and reduces errors. According to a report by Mordor Intelligence, the global CAD/CAM software market

is expected to grow at a CAGR of approximately 8% from 2021 to 2026, highlighting the increasing adoption of these technologies

across various industries, including manufacturing and construction.

By utilizing advanced CAD/CAM software, companies can create precise digital models that dictate CNC cutting

operations with high fidelity, minimizing human error and ensuring that the final products meet stringent specifications.

By utilizing advanced CAD/CAM software, companies can create precise digital models that dictate CNC cutting

operations with high fidelity, minimizing human error and ensuring that the final products meet stringent specifications.

Furthermore, a study published by Technavio forecasts that the adoption of automation in CNC machining will increase by 25% between 2020 and 2024, largely due to the integration of sophisticated CAD/CAM systems. This shift allows for the optimization of cutting paths and speeds, which not only shortens production times but also extends tool life. By systematically analyzing data from past projects, firms can continuously refine their workflow, achieving greater operational efficiency and reducing material wastage. Enhanced CAD/CAM integration thus becomes a cornerstone for businesses aiming to stay competitive in a rapidly evolving market, underscoring the necessity of these technologies in modern CNC cutting workflows.

Analyzing Data: Utilizing Machine Analytics to Improve CNC Workflow Performance

The integration of IoT in CNC cutting techniques has revolutionized the manufacturing landscape, particularly in predictive maintenance. By enabling real-time monitoring and data analysis, manufacturers can anticipate machine failures before they occur. Reports indicate that predictive maintenance can reduce maintenance costs by 25% to 30% and decrease downtime by up to 50%. This transformation is pivotal as manufacturers shift from reactive to proactive strategies, leading to enhanced efficiency and reduced operational risks.

Additionally, the utilization of artificial intelligence (AI) in conjunction with IoT is further refining the predictive capabilities in CNC workflows. AI algorithms enhance data analysis, identifying patterns and anomalies that might not be visible through traditional means. A survey among additive manufacturing experts revealed that 70% believe AI will play a significant role in process optimization and quality control. This shift not only maximizes resource utilization but also elevates overall productivity, heralding a new era in manufacturing efficiency. As businesses harness these technologies, the future of CNC workflow performance looks brighter than ever.

Related Posts

-

Digital Strategies for Enhancing CNC Cutting Efficiency

-

Precision Engineering in China: Elevating Global Manufacturing with the Best Plasma Cutting Technology

-

How to Choose the Best Small CNC Plasma Cutting Machine for Your Business Needs

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

Finding Quality Suppliers for Best Industrial Cutting Tables Effective Strategies for Global Buyers

-

How to Maximize After-Sales Support for the Best CNC Table and Minimize Repair Costs