How to Maximize After-Sales Support for the Best CNC Table and Minimize Repair Costs

In the competitive landscape of manufacturing, after-sales support plays a crucial role in maintaining the operational efficiency of equipment, particularly CNC tables. According to a recent report from Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, underscoring the growing reliance on these advanced machines. Effective after-sales support not only enhances customer satisfaction but also significantly reduces repair costs, which can account for up to 30% of the total cost of ownership for CNC equipment. By implementing proactive maintenance strategies and offering comprehensive support services, manufacturers can optimize the performance of their CNC tables, minimize downtime, and ultimately drive long-term profitability. This blog will explore actionable strategies to maximize after-sales support for CNC tables, ensuring that businesses can thrive in an increasingly automated world.

Understanding the Importance of After-Sales Support in CNC Machinery

After-sales support is a critical aspect in the CNC machinery industry, particularly given the complex nature of these machines and their integral role in manufacturing processes. According to a report by the International Federation of Robotics, over 2.7 million industrial robots were in use worldwide by 2020, with CNC machinery leading the way in precision tasks. This surge in adoption underscores the necessity for robust after-sales support mechanisms to ensure machine longevity and efficient production capabilities.

After-sales support is a critical aspect in the CNC machinery industry, particularly given the complex nature of these machines and their integral role in manufacturing processes. According to a report by the International Federation of Robotics, over 2.7 million industrial robots were in use worldwide by 2020, with CNC machinery leading the way in precision tasks. This surge in adoption underscores the necessity for robust after-sales support mechanisms to ensure machine longevity and efficient production capabilities.

Effective after-sales support can significantly reduce repair costs and downtime. A study published in the Journal of Manufacturing Science and Engineering highlighted that businesses with a reliable support system experienced 30% lower repair costs compared to those lacking such services. Additionally, companies that actively engage in after-sales communications and provide timely support see a 20% increase in customer satisfaction. This connection not only enhances brand loyalty but also fortifies the overall competitive edge in the market, reflecting the growing importance of after-sales support in maintaining optimal CNC machine operations.

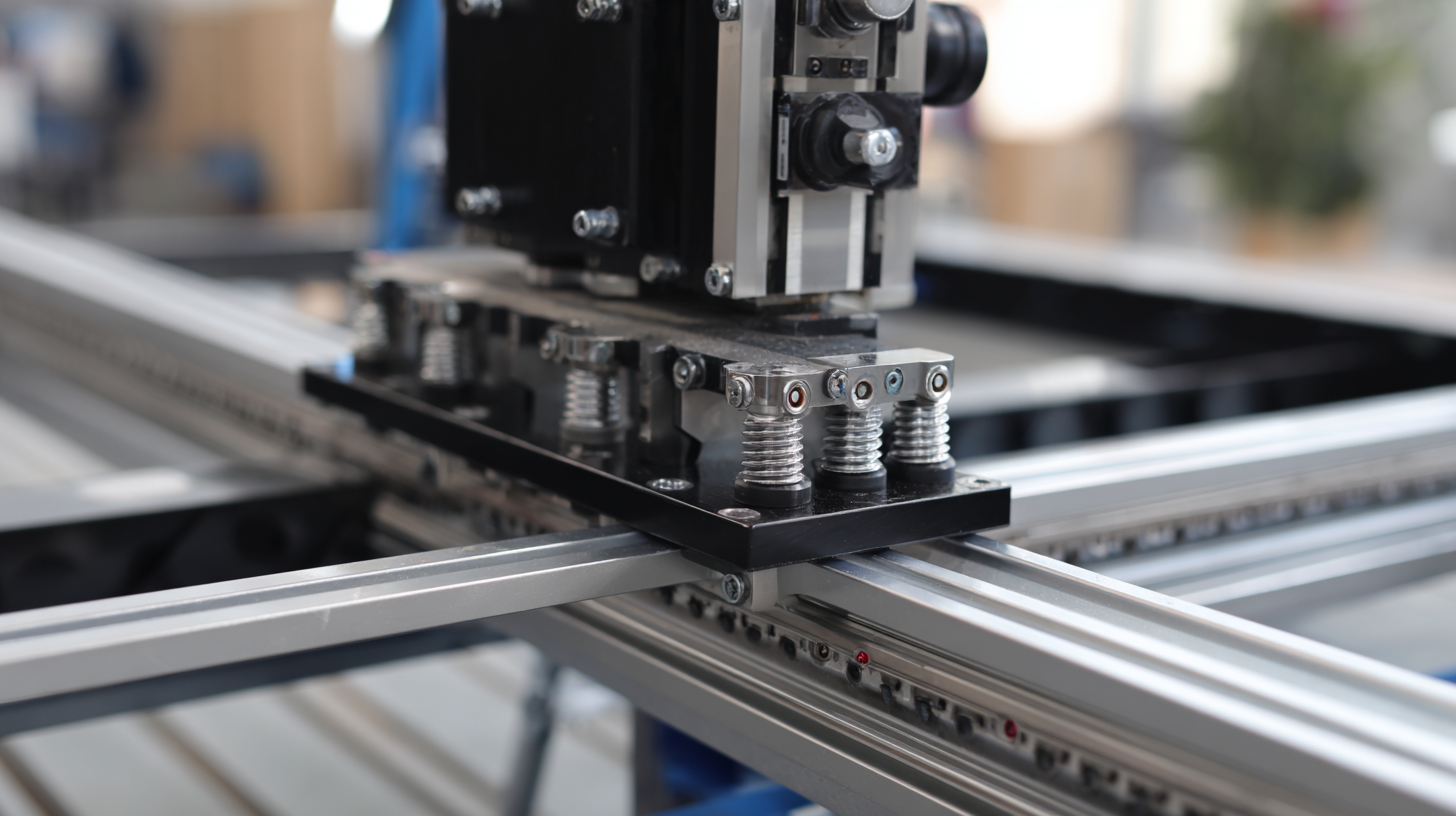

Key Components of Effective After-Sales Support for CNC Tables

Effective after-sales support is crucial in maximizing the operational lifespan of CNC tables while minimizing repair costs. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from $76.9 billion in 2021 to $118.5 billion by 2025, highlighting the increasing dependence of industries on these machines. To ensure optimal performance, manufacturers must focus on key components of after-sales support, including comprehensive training and responsive customer service.

Informed training programs are essential in helping operators effectively utilize CNC machines, reducing the likelihood of operational errors that often lead to costly repairs. A study by the American National Standards Institute (ANSI) indicates that 70% of operational issues arise from inadequate training. Additionally, establishing a strong customer service framework that offers timely support can decrease machine downtime and related expenses. A report by Aberdeen Group found that companies with effective after-sales service can reduce repair costs by up to 30%, emphasizing the importance of investing in customer support initiatives.

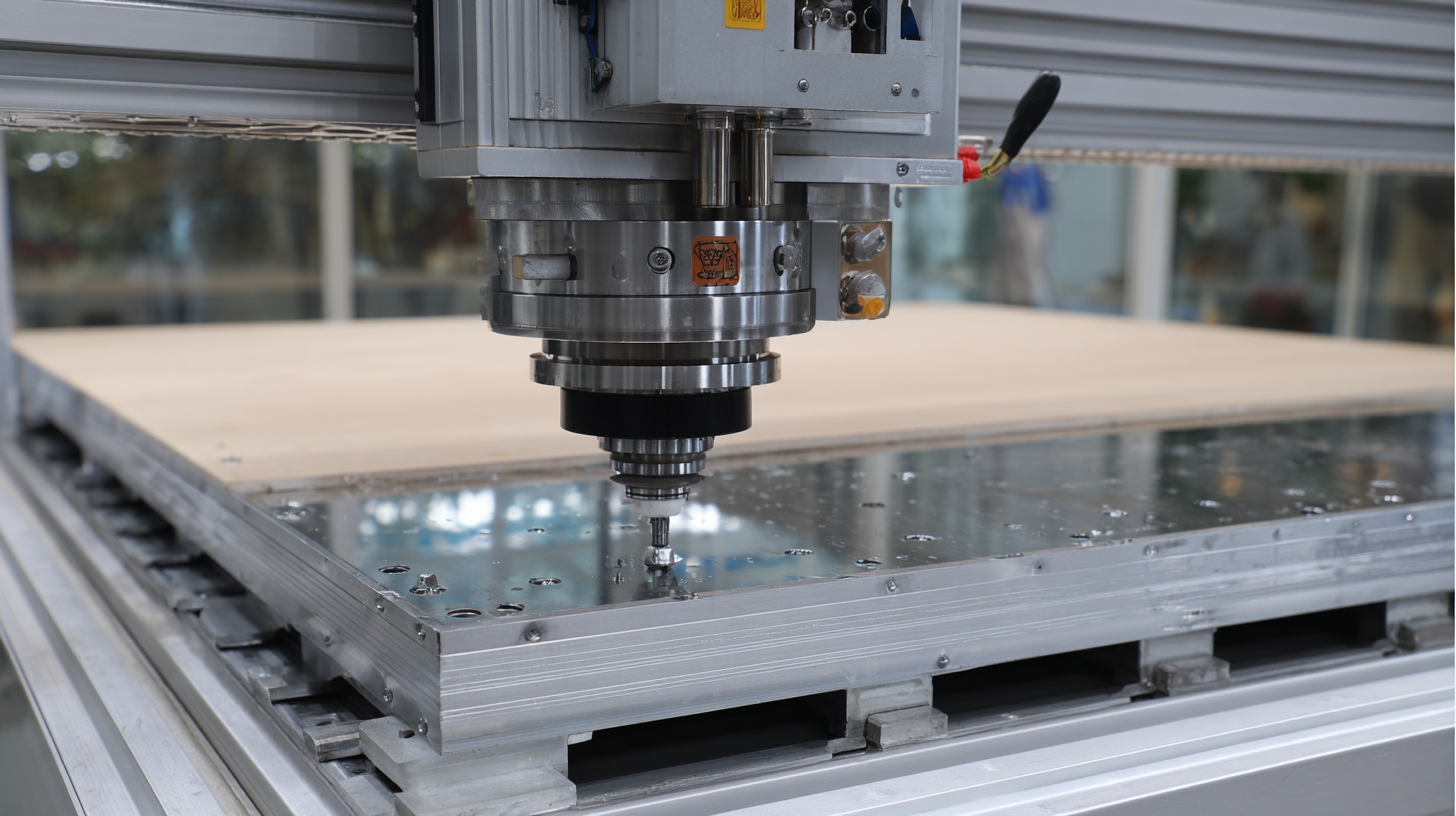

Strategies to Reduce Repair Costs for CNC Table Users

In the competitive landscape of CNC machining, minimizing repair costs is crucial for maintaining operational efficiency. According to a recent survey by TechNavio, the CNC machine market is projected to witness a compound annual growth rate (CAGR) of 7% from 2023 to 2028, highlighting the growing reliance on these machines in various industries. To reduce repair costs effectively, CNC table users should consider implementing a proactive maintenance strategy. Regular inspections and predictive maintenance can help identify potential issues before they escalate into costly repairs. A report from the Institute for Supply Management indicates that predictive maintenance can reduce maintenance costs by 20-30%, allowing companies to allocate their resources more effectively.

Moreover, investing in after-sales support can significantly enhance the longevity of CNC tables. A study by Deloitte reveals that businesses that prioritize after-sales service often experience 20% lower repair and maintenance costs compared to those that do not. Establishing a reliable communication channel with suppliers for timely service and parts can ensure that any issues are resolved swiftly, minimizing downtime and repair expenses. By adopting these strategies, CNC table users can not only reduce their repair costs but also optimize their overall production efficiency.

Analyzing Market Trends and Consumer Expectations in 2025

In 2025, the global NAS market is projected to reach $5.03 billion, with expectations to grow to $13.18 billion by 2033, reflecting a robust compound annual growth rate (CAGR) of 12.8%. This growth indicates a significant consumer focus on efficient storage solutions, emphasizing the importance of maximizing after-sales support for products like CNC tables. Companies that align their services with market trends and consumer expectations can enhance customer satisfaction and loyalty.

**Tip:** Invest in comprehensive training for your customer support team to address consumer needs effectively. A well-informed support team can troubleshoot issues quickly, reducing downtime and minimizing repair costs.

Additionally, with rising standards for after-sales service, businesses should consider leveraging data analytics to better understand consumer behavior and enhance service offerings. By analyzing support requests and market trends, companies can preemptively address common issues and optimize their product maintenance strategies.

**Tip:** Implement a feedback loop where customers can report their experiences, allowing your business to adapt and refine your after-sales processes continually. This proactive approach not only minimizes repair costs but also fosters a strong relationship with your clientele.

Innovative Technologies to Enhance After-Sales Services in the CNC Industry

With advancements in technology, enhancing after-sales support in the CNC industry is becoming increasingly vital. Innovative solutions, such as AI-driven diagnostics and cloud-based monitoring systems, can significantly reduce repair costs and downtime. By implementing these technologies, manufacturers can not only anticipate potential issues before they become critical but also streamline the repair process to ensure minimal disruption to production.

To maximize after-sales support, consider integrating a robust communication platform where customers can easily report issues and interact with support teams. This proactive approach fosters a collaborative environment and builds trust with clients, ultimately leading to improved customer satisfaction. Additionally, adopting predictive maintenance strategies based on real-time data can help identify trends and reduce unexpected failures, ensuring CNC tables operate at peak efficiency.

Emphasizing training and education for both customers and support staff is also essential. Providing workshops and instructional materials about the proper use and maintenance of CNC machines empowers your clients and reduces the likelihood of misuse or negligence that can lead to costly repairs. By focusing on innovative support technologies and strong customer engagement, businesses in the CNC sector can drive down costs and enhance their competitive edge in a rapidly evolving market.