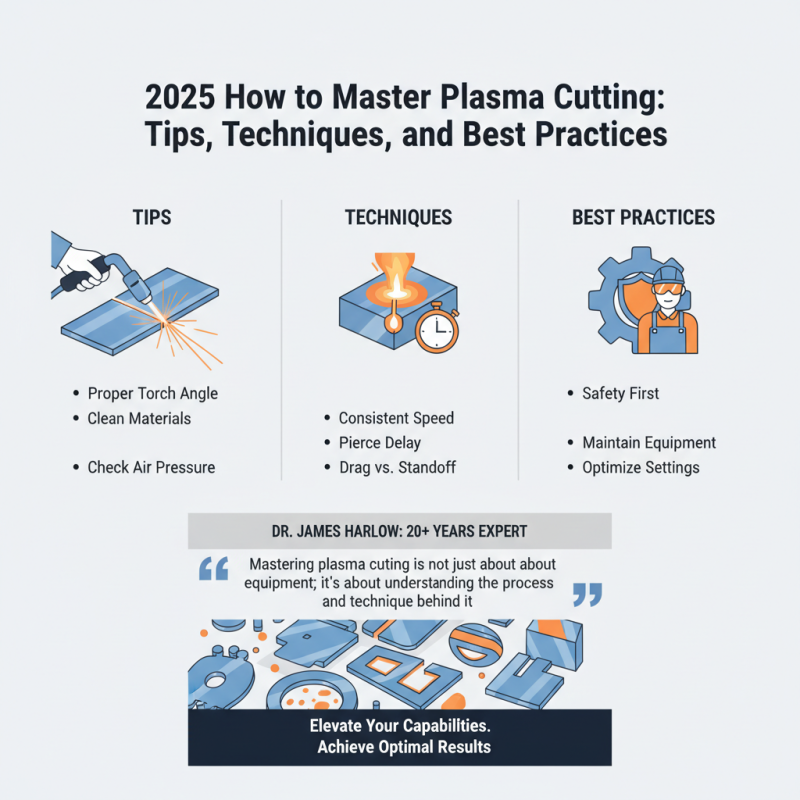

2025 How to Master Plasma Cutting: Tips, Techniques, and Best Practices

Plasma cutting has emerged as a revolutionary technique in the metalworking industry, providing precision and efficiency that traditional methods often cannot match. As an expert in the field, Dr. James Harlow, a renowned metallurgist with over two decades of experience, states, “Mastering plasma cutting is not just about the equipment; it’s about understanding the process and technique behind it.” In the rapidly evolving landscape of fabrication and manufacturing, the ability to effectively utilize plasma cutting can significantly enhance productivity and accuracy.

As we delve into the essential tips, techniques, and best practices for mastering plasma cutting, it’s crucial to understand both the fundamental principles and the nuances that can distinguish an amateur from a skilled practitioner. From selecting the appropriate torch to managing material thickness and speed, each decision can greatly impact the quality of the finished product. This guide aims to arm you with the knowledge needed to elevate your plasma cutting capabilities, ensuring that you achieve optimal results with every project you undertake.

Understanding Plasma Cutting: Basics and Applications

Plasma cutting is a versatile and efficient technique widely used in metal fabrication, automotive, and construction industries. By employing a high-velocity jet of ionized gas, or plasma, users can cut through electrically conductive materials with precision and minimal distortion. According to a report by the Fabricators and Manufacturers Association, plasma cutting technology has seen a growth rate of approximately 5.7% annually, reflecting its increasing popularity among fabricators looking for speed and efficiency in their operations.

Understanding the basics of plasma cutting is essential for any apprentice or professional in the field. The process begins with creating an electrical channel of ionized gas between an electrode and the workpiece. This initiates a conductive plasma arc, allowing the operator to guide the nozzle and cut through metals like aluminum, steel, and stainless steel with varying thicknesses. An analysis from the American Welding Society estimates that nearly 30% of all metal fabrication projects now employ plasma cutting processes, highlighting the technology's relevance in modern applications.

Applications of plasma cutting extend beyond simple metal cutting. Industries utilize this technology for tasks such as gouging, beveling, and piercing, accommodating a diverse range of products from intricate automotive components to large structural steel pieces. Furthermore, innovations in plasma technology continue to enhance cutting speed and accuracy, opening new avenues for creative manufacturing solutions. As the industry evolves, mastering the subtleties of this process will be crucial for fabricators aiming to stay competitive in a rapidly changing landscape.

2025 How to Master Plasma Cutting: Tips, Techniques, and Best Practices

| Aspect | Details |

|---|---|

| What is Plasma Cutting? | A cutting process that uses a jet of ionized gas to cut through electrically conductive materials. |

| Common Applications | Metal fabrication, automotive repair, construction, and sculpture. |

| Key Equipment | Plasma cutter, air compressor, safety gear. |

| Safety Precautions | Use appropriate PPE, ensure proper ventilation, and be aware of fire hazards. |

| Cutting Techniques | Maintain a consistent speed, keep the torch at a proper distance, and adjust settings based on material thickness. |

| Advantages | Fast cutting speed, precision cuts, minimal heat-affected zone. |

| Disadvantages | Limited to conductive materials, requires skill and practice. |

| Best Practices | Regular maintenance of equipment, using quality consumables, and continuous skill improvement. |

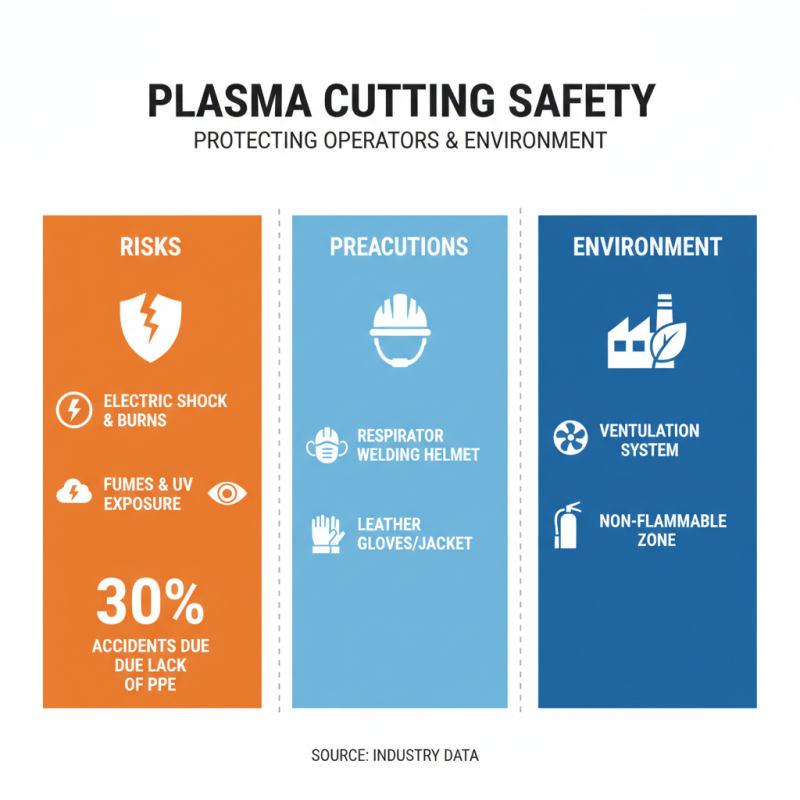

Essential Safety Precautions for Plasma Cutting Operations

Plasma cutting is a highly efficient method for cutting through various metals, but it comes with significant safety risks that operators must take seriously. According to industry data, over 30% of plasma cutting accidents are attributed to inadequate safety precautions. To mitigate these risks, it is essential to implement comprehensive safety measures that protect both the operator and the surrounding environment.

One key safety precaution is the use of appropriate personal protective equipment (PPE). Operators should always wear protective eyewear specifically designed to shield against ultraviolet and infrared radiation, as well as heavy-duty gloves and fire-resistant clothing. According to the American Welding Society, failing to wear adequate PPE can increase the risk of injuries by up to 40%. Additionally, ensuring that the work area is well-ventilated is crucial, as plasma cutting generates potentially harmful fumes and gases.

**Tips**: Prior to starting any cutting operation, conduct a thorough inspection of the equipment to identify any wear or damage that could pose a hazard during use. Practicing proper grounding techniques can also help prevent electrical shocks. Furthermore, having a fire extinguisher nearby and being trained in its use can significantly reduce the impact of any accidental fires that may occur during operations, given that studies indicate that nearly 20% of plasma cutting incidents are fire-related. Safety is not just a precaution; it is an integral aspect of efficient plasma cutting operations.

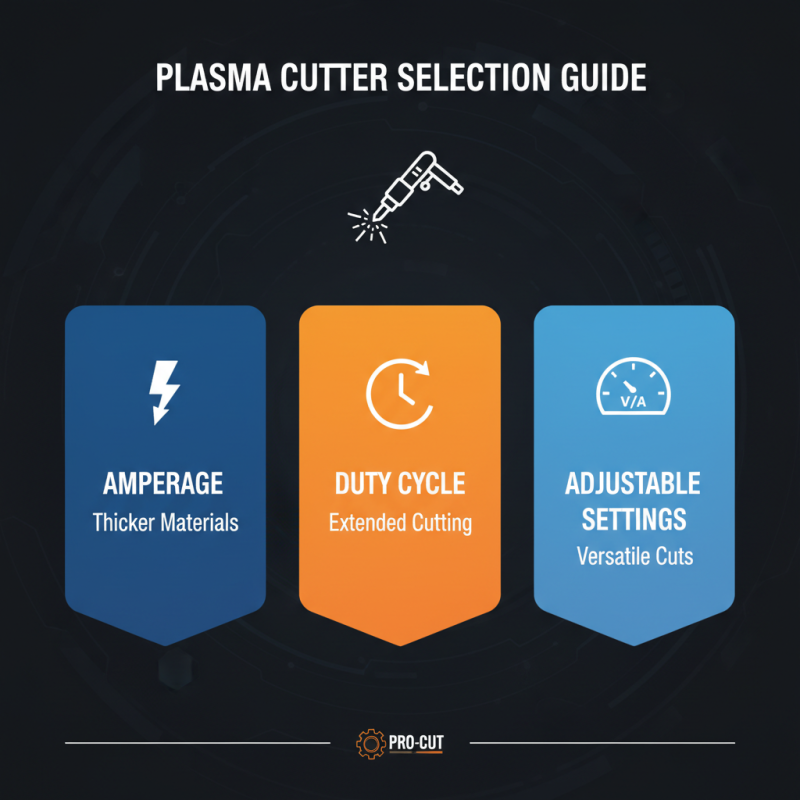

Choosing the Right Plasma Cutting Equipment and Accessories

When it comes to plasma cutting, selecting the right equipment and accessories is crucial for achieving precise and efficient results. The core component of any plasma cutting setup is undoubtedly the plasma cutter itself. When choosing a plasma cutter, consider factors such as amperage, duty cycle, and cutting thickness capabilities. A higher amperage allows for cutting through thicker materials, while a robust duty cycle ensures that the machine can operate for extended periods without overheating. Additionally, look for models that offer adjustable settings for voltage and current, enabling you to customize your cutting process for various materials.

Accessories play a significant role in enhancing plasma cutting performance. Plasma cutting torches, which come in different sizes and styles, are essential for controlling the cutting arc effectively. Opt for a torch that fits comfortably in your hand and allows for precision cutting. Furthermore, consumables such as electrodes and nozzles should be chosen based on the specific requirements of the materials you plan to cut. Regularly replacing these components can significantly improve cutting quality and longevity. Protective equipment, including gloves and safety goggles, is also necessary to ensure safety during operations. By carefully selecting the right plasma cutting equipment and accessories, you can significantly enhance your overall cutting experience and results.

Techniques for Achieving Precision in Plasma Cutting

Achieving precision in plasma cutting is essential for obtaining high-quality cuts with minimal kerf and distortion. One of the foundational techniques for precision is maintaining the correct standoff distance. This is the distance between the cutting nozzle and the material being cut, which should be consistent throughout the process. A proper standoff distance prevents excessive wear on the nozzle and ensures a stable arc, leading to cleaner cuts. Operators should regularly check and adjust this distance to accommodate various material thicknesses and types for optimal performance.

Another important technique is to select the appropriate cutting speed. Moving too quickly can result in rough edges and poor penetration, while cutting too slowly may cause excessive melting and warping of the material. It is vital to find a balance based on the specific thickness and material type, as well as the capabilities of the plasma cutting equipment. Experimenting with various speeds on scrap material can provide valuable insight into the optimal settings for achieving precise cuts. Moreover, using a steady hand and smooth movements further improves the overall quality of the cut, ensuring consistent results and enhancing the operator's skill over time.

2025 Plasma Cutting Precision Techniques

This chart represents the effectiveness of various plasma cutting techniques measured by precision rate. The data showcases the implementation success rates of different techniques.

Maintenance Best Practices for Optimal Plasma Cutting Performance

Maintaining plasma cutting equipment is crucial for ensuring optimal performance and longevity. According to a report from the Fabricators & Manufacturers Association, proper maintenance can increase the lifespan of plasma cutting machines by up to 50%. Regular inspections of consumables such as electrodes and nozzles can prevent unnecessary downtime due to equipment failure. It's recommended to replace these parts based on usage hours rather than waiting until they show signs of wear, as this proactive approach can enhance cutting quality and reduce operating costs.

In addition, keeping the compressed air supply clean and dry is essential. Contaminants in the air can lead to poor cut quality and increased wear on plasma components. The American Welding Society emphasizes the importance of using air dryers and filtration systems to maintain air purity. Routine maintenance practices, including checking the grounding and ensuring that the torch is aligned correctly, can also significantly impact the effectiveness of plasma cutting operations. According to industry experts, implementing these maintenance best practices can lead to improved productivity and a noticeable reduction in operational costs.

Related Posts

-

Precision Engineering in China: Elevating Global Manufacturing with the Best Plasma Cutting Technology

-

7 Best HD Plasma Cutters for Precision Metal Cutting in 2023

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers

-

Exploring Growth Trends in Plasma Cutting Table Sales at the 138th Canton Fair 2025: A Data-Driven Perspective

-

Maximizing Efficiency: How a Plasma Cutting Table Transforms Metal Fabrication Workflows

-

The Future of Metal Fabrication with Advanced Plasma Cutting Tables