Innovative Uses of the Best CNC Table in Modern Manufacturing Solutions

In the ever-evolving landscape of modern manufacturing, the role of a CNC table has emerged as a pivotal element in enhancing productivity and precision across various industries. This blog delves into the innovative uses of the best CNC tables, exploring their technical specifications and providing a comprehensive tutorial to empower manufacturers in maximizing their potential. From intricate design features that cater to different materials to advanced software integration that streamlines operations, understanding the capabilities of CNC tables is essential for today’s manufacturers seeking a competitive edge. Join us as we uncover the transformative impact of CNC technology, highlighting how these sophisticated machines can revolutionize production processes and foster creative solutions in the manufacturing realm.

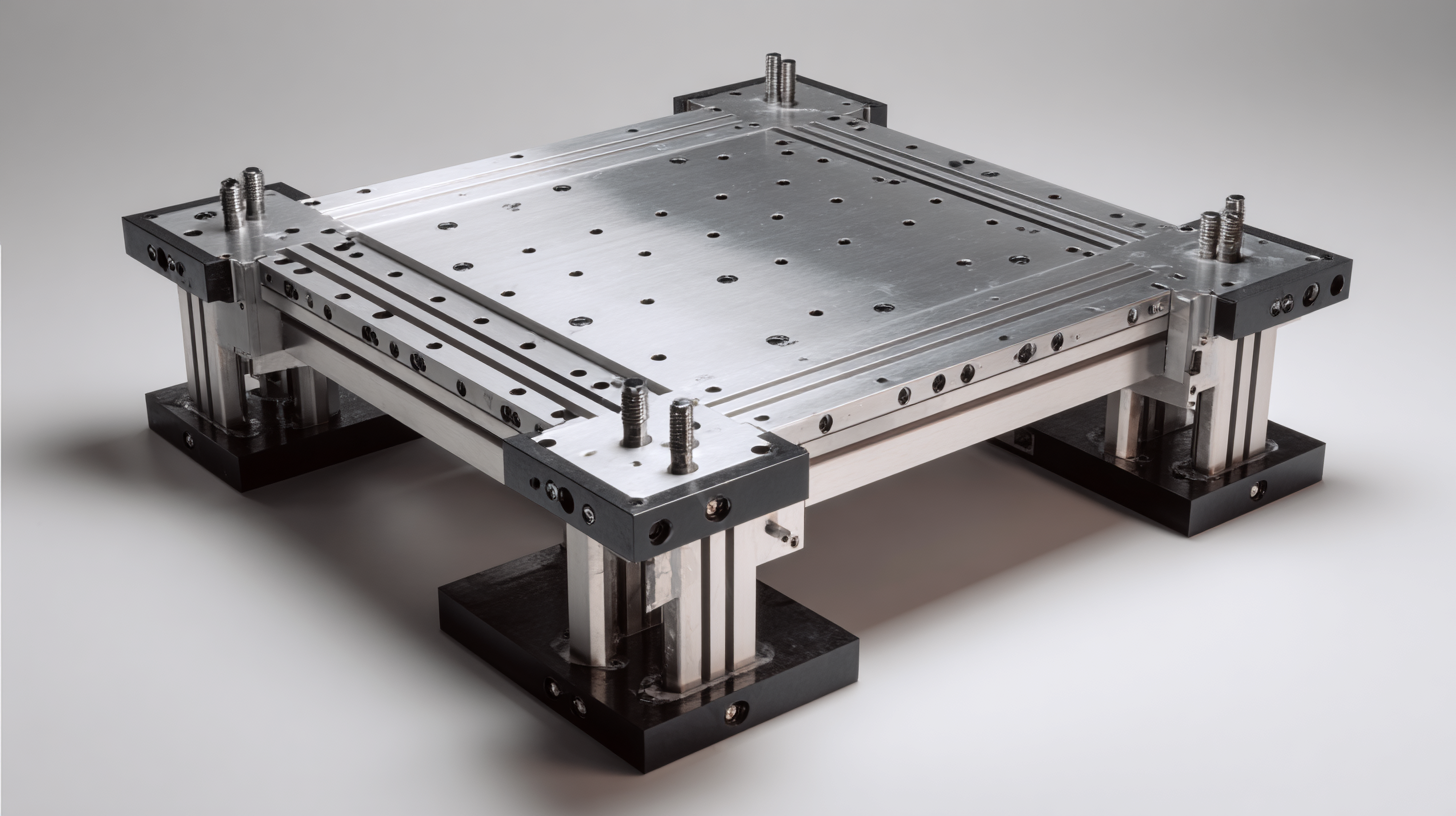

Understanding CNC Table Technology and Its Impact on Manufacturing

CNC table technology is revolutionizing modern manufacturing by incorporating advanced techniques that enhance precision, efficiency, and versatility in production processes. As manufacturers face growing demands for better quality and faster turnaround times, CNC tables can integrate innovative solutions such as cold plasma technology. This non-thermal approach offers effective food processing methods, showcasing how manufacturing technologies are embracing sustainability and safety to meet evolving consumer needs.

Moreover, as the chip manufacturing industry grapples with significant environmental challenges, applying CNC table technology can optimize production methods, reducing waste and improving eco-efficiency. These advancements in CNC machining not only streamline operations but also align with global efforts to minimize environmental impact. Innovative methods such as Failure Modes, Effects, and Criticality Analysis (FMECA) are being developed to further enhance CNC tool reliability, ultimately leading the way toward a more sustainable and responsible manufacturing landscape.

Innovative Uses of CNC Table Technology in Modern Manufacturing

Exploring Innovative Features of Top CNC Tables for Enhanced Productivity

In modern manufacturing, the integration of advanced CNC table technology is transforming productivity across various sectors. The latest models incorporate innovative features such as

adaptive feed rates and AI-driven toolpath optimization, significantly enhancing operational efficiency. Reports indicate that manufacturers using state-of-the-art CNC tables can increase output by as much as 30%, while reducing material waste by 15%. These improvements are critical as industries face increasing pressure to meet quality standards and reduce production costs simultaneously.

Furthermore, a 2025 analysis of quality management trends reveals that organizations adopting CNC machinery with real-time monitoring features are better positioned to maintain consistent quality. Enhanced data analytics capabilities allow manufacturers to swiftly identify and rectify discrepancies, ensuring that the final products meet stringent quality benchmarks. With 20 leading startups emerging in the sphere of automation and quality management, the synergy between innovative CNC technology and robotics is set to redefine manufacturing practices, driving unprecedented productivity and quality assurance.

Key Strategies for Optimizing CNC Table Operations in Manufacturing

In modern manufacturing, optimizing CNC table operations is crucial for achieving efficiency and precision. A recent report by MarketsandMarkets reveals that the CNC machine market is expected to grow from $63 billion in 2020 to $100 billion by 2026, indicating a significant shift toward automation and advanced manufacturing techniques. To harness this potential, manufacturers must focus on effective strategies that streamline workflows and maximize output.

One key strategy involves implementing real-time monitoring and data analytics to track CNC table performance. According to a study by McKinsey, companies that leverage data can boost their productivity by up to 20%. By integrating IoT sensors and predictive maintenance tools, operators can minimize downtime, reduce waste, and improve the overall lifecycle of their CNC tables. Furthermore, standardizing processes and investing in employee training are essential for ensuring that teams can operate these advanced machines efficiently, leading to enhanced product quality and reduced operational costs.

Collaboration with software providers to enhance programming capabilities also plays a vital role in optimizing CNC operations. A report from Grand View Research states that the global CNC software market is projected to reach $5.3 billion by 2025. By utilizing advanced CAD/CAM software, manufacturers can significantly reduce lead times and improve accuracy, ensuring that their CNC tables are used to their fullest potential. Implementing these strategies not only boosts operational efficiency but sets the foundation for sustainable growth in the competitive manufacturing landscape.

Real-World Applications of CNC Tables in Various Industries

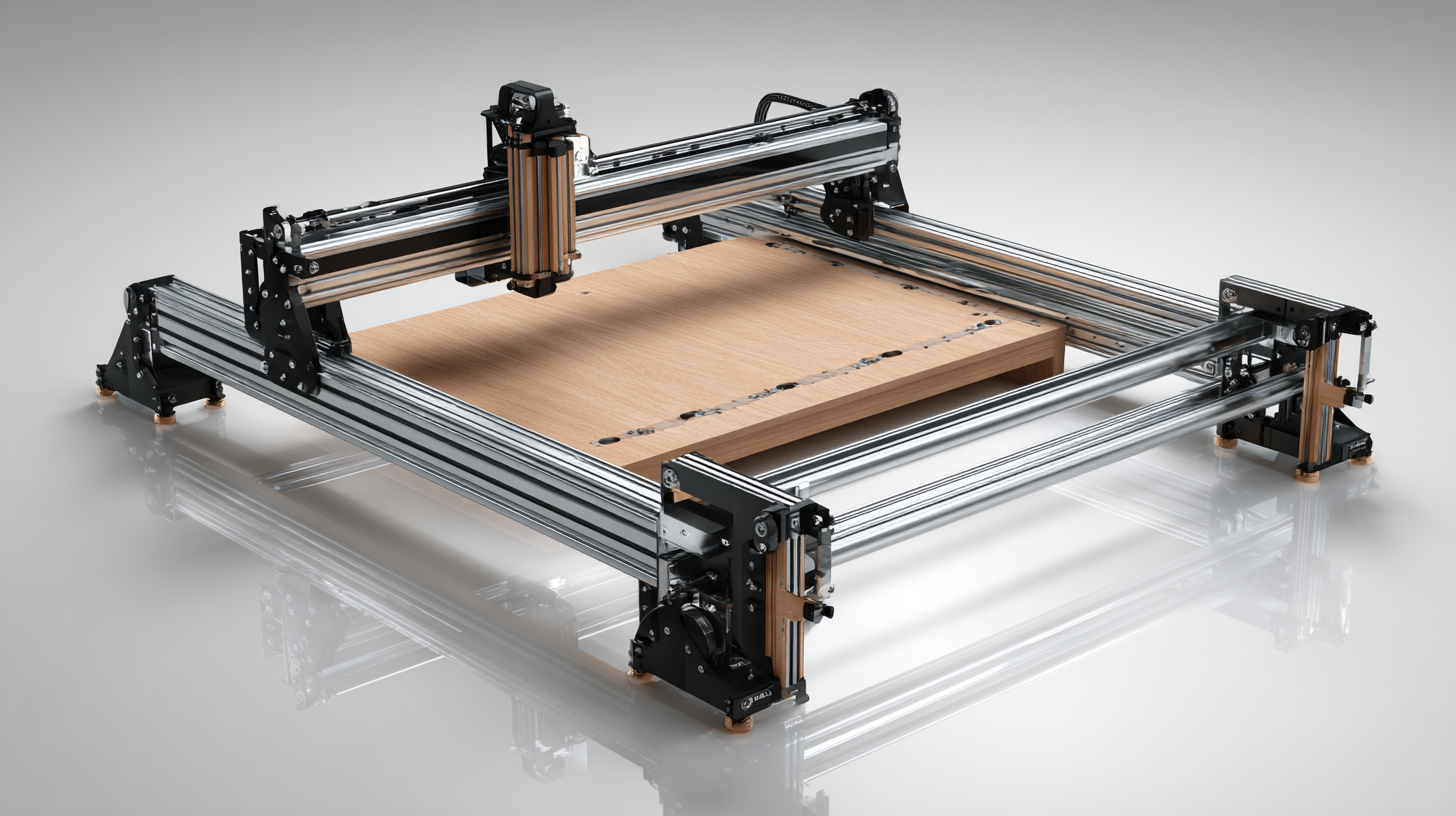

CNC tables have revolutionized manufacturing across various industries, offering unparalleled precision and flexibility. One of the most prominent applications can be found in the woodworking sector, where CNC tables automate the cutting and shaping of intricate designs. This automation allows artisans to produce complex patterns with consistency and speed, significantly reducing labor costs while enhancing product quality. From custom furniture to intricate carvings, the adaptability of CNC technology meets the demands of both mass production and unique bespoke projects.

In the automotive industry, CNC tables play a crucial role in machining and prototyping components. Manufacturers utilize these tables to create highly precise parts that meet stringent safety and performance standards. The ability to quickly iterate designs and manufacture test components significantly accelerates the production process, allowing companies to bring innovations to market faster. Moreover, industries such as aerospace and electronics benefit from CNC tables’ capacity to handle a variety of materials, including metals, plastics, and composites, showcasing their versatility across different applications.

Innovative Uses of the Best CNC Table in Modern Manufacturing Solutions - Real-World Applications of CNC Tables in Various Industries

| Industry | Application | Material | Benefits |

|---|---|---|---|

| Aerospace | Precision component manufacturing | Aluminum alloys | High accuracy, weight reduction |

| Automotive | Custom part creation | Steel, plastics | Speed, flexibility in production |

| Medical Devices | Manufacturing surgical instruments | Titanium | Biocompatibility, precision |

| Electronics | Circuit board milling | Copper, FR-4 | High precision, reduced waste |

| Furniture | Custom cabinetry | Wood, MDF | Intricate designs, efficiency |

Future Trends in CNC Table Technology and Their Implications for Manufacturing

The evolution of CNC table technology is paving the way for smarter and more efficient manufacturing solutions. As industries increasingly embrace automation, CNC tables are being integrated with advanced technologies such as IoT, artificial intelligence, and machine learning. This integration not only enhances precision and speed but also facilitates real-time data analytics for better decision-making. Manufacturers can now monitor performance metrics remotely, anticipate equipment failures, and optimize production schedules, creating a more responsive and flexible manufacturing environment.

Moreover, the rise of sustainable practices in manufacturing is influencing the design and functionality of CNC tables. Future trends suggest a shift towards energy-efficient machines that minimize waste and maximize resource use. With the advent of eco-friendly materials and processes, CNC tables are becoming more than just tools; they are integral components of a sustainable manufacturing ecosystem. As we look ahead, the combination of innovative technology and environmental consciousness will redefine how products are designed and manufactured, ensuring that CNC tables are not only effective but also responsible contributors to the industry.