Exploring Innovative Alternatives to the Best Cutting Table for Your Workshop

In the world of manufacturing and woodworking, the choice of tools can significantly impact efficiency and precision. Among these tools, the cutting table stands out as a cornerstone of any workshop, playing a crucial role in the quality of the finished product. According to a recent industry report by MarketsandMarkets, the global woodworking machinery market is projected to reach $10.5 billion by 2026, driven in part by advancements in cutting technology and the increasing demand for customizable and efficient cutting tables. This growth highlights the necessity for innovative alternatives that can not only meet but exceed the expectations of modern manufacturers.

As we explore various alternatives to traditional cutting tables, we delve into options that enhance productivity and precision while also considering sustainability and cost-effectiveness, all crucial elements in today's competitive manufacturing landscape.

Innovative Materials for Cutting Tables: A New Era in Workshop Design

In recent years, the workshop design landscape has witnessed a shift towards innovative materials that enhance functionality and sustainability. The emergence of 4D printing materials exemplifies this trend, introducing smart, shape-changing materials that respond to various stimuli. These materials can significantly alter the workflow in cutting tables, allowing for adaptive designs that can optimize the cutting process based on real-time needs. As manufacturers continue to explore these technologies, the applications for cutting tables become increasingly sophisticated, enabling users to achieve a higher level of precision and efficiency.

Moreover, the integration of sustainable building materials into workshop design is gaining momentum. Recent studies indicate that advancements in production technologies have led to the classification of sustainable materials that not only meet environmental standards but also enhance performance. This aligns with the industry’s growing commitment to reducing waste and promoting eco-friendly practices. With innovative solutions emerging, workshops can leverage these materials to create cutting tables that are not only functional but also aligned with a sustainable vision for the future, providing an array of choices for both hobbyists and professionals alike.

Ergonomic Considerations: Enhancing Comfort and Efficiency in Your Workspace

When setting up a workshop, choosing the right cutting table is just the beginning. Ergonomic considerations play a crucial role in enhancing comfort and efficiency, ultimately leading to a more productive workspace. An ideal cutting table should accommodate your height and the types of projects you undertake, allowing you to work without straining your back or arms.

Tip: To determine the right height for your cutting table, standing straight, bend your elbows at a 90-degree angle. The table should ideally reach your forearms, enabling you to work comfortably. Adjustable tables can also provide flexibility, accommodating different tasks and users alike.

Moreover, the layout of your workspace can greatly affect your comfort level. Ensure that your tools and materials are within easy reach to minimize bending and stretching, which can lead to fatigue over time.

Tip: Organize your workstation by using wall-mounted shelves or tool organizers. This keeps essentials easily accessible, helping to maintain an efficient workflow while reducing the risk of injury from overextension. Remember, the goal is to create a space that promotes not just great output, but also your well-being.

Modular Cutting Tables: Maximizing Flexibility for Diverse Projects

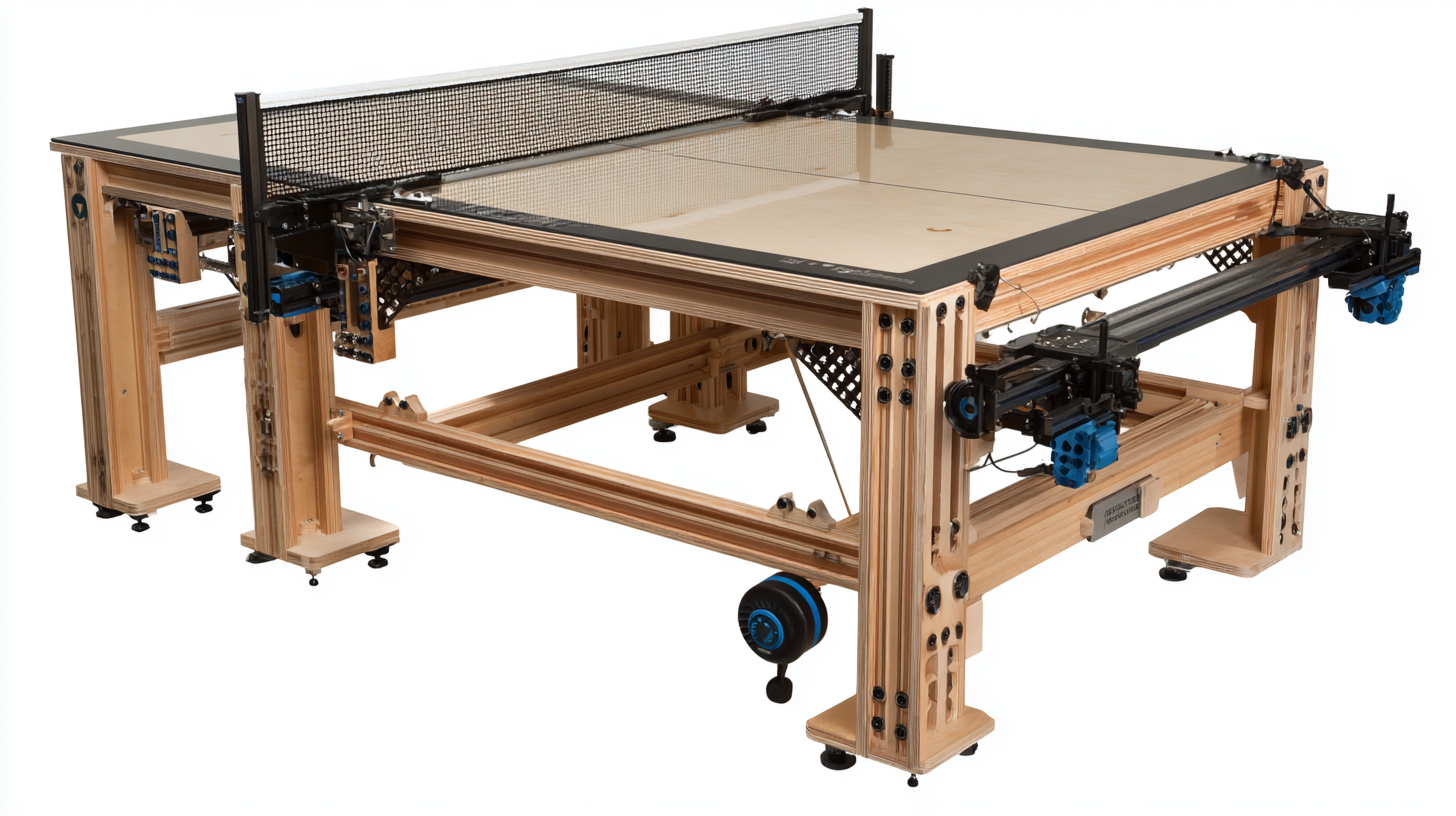

When it comes to setting up an efficient workshop, the choice of cutting table can significantly influence the productivity and creativity of the space. Modular cutting tables have emerged as a popular option among craftsmen, designers, and hobbyists alike, offering a solution that maximizes flexibility to accommodate a wide range of projects. These tables allow users to customize their workspace according to specific tasks, seamlessly transitioning from larger projects, such as furniture assembly, to finer tasks like intricate crafts.

The beauty of modular cutting tables lies in their adaptability. Various components can be added or removed, enabling users to create a cutting surface that fits their precise needs at any moment. Whether integrating storage options for tools and materials or adjusting the height for different projects, modular designs provide a level of versatility that traditional fixed tables simply cannot match. This functionality not only enhances efficiency but also fosters a more organized and dynamic working environment, empowering creators to explore new ideas without being constrained by their setup.

Smart Technology Integration: The Future of Cutting Table Functionality

In today’s rapidly evolving workshop landscape, the integration of smart technology into cutting tables is transforming how craftspeople and professionals approach their projects. The future of cutting table functionality hinges on the ability to seamlessly blend traditional craftsmanship with innovative tech solutions. Imagine a cutting table equipped with digital guides that adapt to the material’s dimensions, giving users precise cutting lines and minimizing waste. Such advancements not only streamline workflows but also enhance the accuracy and safety of cutting tasks.

Moreover, smart cutting tables can be equipped with sensors that monitor pressure and angle, providing real-time feedback to ensure optimal cuts every time. This level of integration opens the door to enhanced automation, where a cutting table can be programmed to execute complex patterns with minimal manual intervention. As we explore these innovative alternatives, it becomes clear that the future of workshops lies in embracing technology that amplifies our creative capabilities, enabling us to push the boundaries of what we can create.

Sustainable Manufacturing Practices: Eco-friendly Options for Your Workshop

Sustainable manufacturing practices are gaining traction in workshops around the globe, as an increasing number of artisans and industries look to reduce their environmental impact. According to a report by the Global Manufacturing Forum, about 70% of manufacturers are now actively seeking eco-friendly alternatives to traditional materials and processes. This shift is not just a trend; it's becoming a necessity for those wanting to remain competitive in a market that increasingly values sustainability.

One innovative option for workshop cutting tables is the use of reclaimed wood, which minimizes waste and preserves resources. Studies indicate that reclaimed wood can save up to 50% more energy compared to newly harvested timber, making it a great choice for environmentally-conscious makers. Additionally, manufacturers are turning to composite materials made from recycled plastics and natural fibers, which not only reduce landfill waste but also enhance the durability of cutting surfaces. By investing in these sustainable alternatives, workshops can significantly contribute to a circular economy and promote responsible resource management, aligning their practices with global sustainability goals.