2026 How to Use a Computerized Plasma Cutter Effectively?

In recent years, the demand for precision in metal fabrication has skyrocketed. A significant part of this trend can be attributed to the increasing popularity of the computerized plasma cutter. According to a report by MarketsandMarkets, the plasma cutting market is projected to reach $4.2 billion by 2025. This growth highlights the need for effective use of technology in production processes.

A computerized plasma cutter offers unmatched accuracy and speed. It can cut various materials, from mild steel to aluminum, with minimal waste. However, operating such advanced equipment requires skill and knowledge. Many users often overlook the importance of settings and proper maintenance, which can lead to inefficiencies. A report from the Fabricators & Manufacturers Association indicates that poorly maintained equipment can reduce productivity by up to 25%.

Learning to maximize the use of a computerized plasma cutter is essential. Understanding the nuances of the software and fine-tuning the machine can significantly improve outcomes. Mistakes in operation can lead to costly errors and material loss. Reflecting on past experiences can pave the way for better practices in the future. Embracing this technology means committing to continual learning and adaptation in the ever-evolving fabrication landscape.

Understanding the Basics of Computerized Plasma Cutters

Computerized plasma cutters are powerful tools used for cutting metal with precision. They use an electric arc and compressed gas to create a high-temperature plasma jet. This jet easily melts through various types of metal, making it suitable for fabrication and welding projects. Understanding the basic components is essential to operate these machines effectively.

The setup includes a computer, a cutting torch, and a gas supply system. Getting familiar with the software is vital, as it allows users to create detailed designs. Additionally, adjusting the settings for speed and power is crucial. A consistent speed results in cleaner cuts, while the power affects the depth of the cut. Small mistakes in settings can lead to uneven edges or excessive slag buildup.

Practicing on scrap materials can help in honing skills. It's easy to underestimate the amount of preparation needed. Even small adjustments in distance can affect the cut quality. Be open to learning from errors, as each cut reveals areas for improvement. Regular maintenance of the machine ensures longevity and optimal performance.

Key Components and Features of a Computerized Plasma Cutter

Computerized plasma cutters offer precision and efficiency for cutting various materials. Key components shape their performance. The cutting torch is crucial; it generates the plasma arc. This arc melts the material while the gas flow makes cutting easy. The control system guides the torch for accurate movements. It allows programming complex designs seamlessly.

Tips: Regular maintenance of the torch enhances cutting quality. Dirty nozzles lead to poor results. Check the gas supply; a constant flow is essential.

Expect some initial challenges when using these machines. Calibration can be tricky. Users might struggle with settings. Experimenting with different materials can also yield varied outcomes. Understanding your cutter's settings will improve performance. Doing so helps avoid wastage and ensures precise cuts.

Step-by-Step Setup for Using a Computerized Plasma Cutter

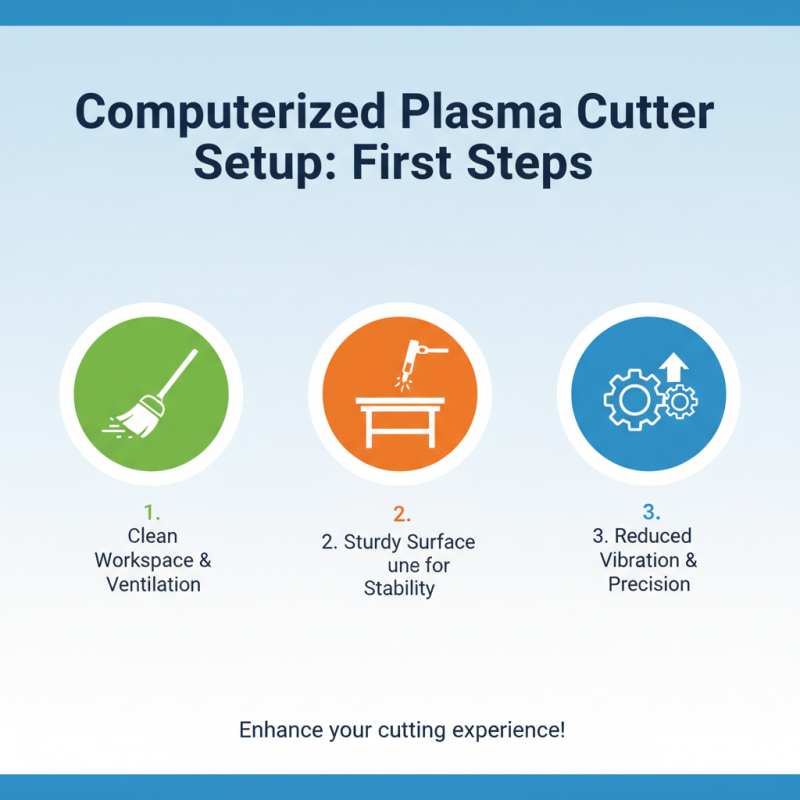

Setting up a computerized plasma cutter can be a rewarding experience. Begin by ensuring your workspace is clean. Clear out debris and ensure good ventilation. Place the cutter on a sturdy surface. The stability of the equipment is crucial. It reduces vibrations and enhances precision.

Next, connect the power source. Ensure that all connections are secure. Double-check voltage settings. A wrong voltage can lead to poor performance. After connecting the power, set up the gas supply. Make sure the gas line is free of leaks. Testing connections is vital to avoid accidents.

Once everything is in place, load your design into the software. Familiarize yourself with the interface. It can be intimidating at first. You might run into errors when importing files. Take time to troubleshoot. Adjust your settings and ensure the design fits your material correctly. Remember, practice makes perfect. Don't be discouraged by initial mistakes. Each cut offers a learning opportunity.

Techniques for Achieving Precision Cuts with a Plasma Cutter

Achieving precision cuts with a computerized plasma cutter requires a blend of technique and preparation. Begin by selecting the right thickness of material. The ideal amperage varies depending on the metal type and thickness. Calibrate the machine settings carefully before starting. This helps in achieving consistent cuts. Sometimes, adjusting the speed can dramatically improve results, so don’t hesitate to experiment.

Pay close attention to the cutting path. A steady hand is essential. Maintain a uniform distance between the torch and the workpiece. This ensures a clean cut and minimizes slag. However, even experienced users can make mistakes. Overheating the material or uneven feeding can lead to rough edges. In such cases, checking machine operation after each use is crucial.

Practicing on scrap materials will boost confidence. It allows you to learn from mistakes without wasting quality sheets. Review cuts frequently; note what went wrong. Documenting these observations helps refine techniques. Remember, even small adjustments can lead to significant improvements over time. In the end, perseverance and attention to detail are your best allies in mastering precision with plasma cutting.

2026 Precision Cuts with a Computerized Plasma Cutter

This bar chart illustrates the cutting speeds (in inches per minute) achievable with a computerized plasma cutter across various thicknesses of steel. As the material thickness increases, the cutting speed typically decreases, highlighting the need for adjustments in settings for optimal performance.

Safety Precautions to Consider When Using Plasma Cutting Technology

When using a computerized plasma cutter, safety should always be the number one priority. Protective gear is essential. Wear safety goggles to shield your eyes from bright arcs and flying debris. A proper welding helmet can ensure that your face is protected too. Gloves should always be worn. They help prevent cuts and burns.

Ensure the workspace is clear and well-lit. Clutter can lead to accidents. Flammable materials should be stored away. Remember, the plasma cutter generates intense heat. Sparks can ignite nearby items. Regularly check the equipment for any faults. A malfunction can pose significant risks.

Always maintain a safe distance from the cutting area. Stand outside the direct line of fire. It’s also wise to have a fire extinguisher within reach. Even experienced users can overlook simple precautions. Be mindful of your surroundings. Overconfidence can lead to mistakes. Taking the time to reflect on safety practices can save lives.

2026 How to Use a Computerized Plasma Cutter Effectively? - Safety Precautions to Consider When Using Plasma Cutting Technology

| Safety Precaution | Importance | Recommended Tools | Frequency of Use |

|---|---|---|---|

| Wear Protective Gear | Prevents burns and injuries | Gloves, goggles, fire-retardant clothing | Always |

| Ensure Proper Ventilation | Reduces inhalation of harmful fumes | Ventilation fans, exhaust systems | Always |

| Keep Fire Extinguishers Accessible | Essential in case of fire emergencies | Class D fire extinguishers | Always |

| Regular Equipment Maintenance | Ensures safety and efficiency | Maintenance tools, manuals | Monthly |

| Understand Material Properties | Prevents mishaps during cutting | Material safety data sheets | Always |

Related Posts

-

The Future of Metal Fabrication with Advanced Plasma Cutting Tables

-

The Future of Precision with CNC Plasma Cutting Tables in Manufacturing

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers

-

Maximizing Efficiency: How a Plasma Cutting Table Transforms Metal Fabrication Workflows

-

7 Best HD Plasma Cutters for Precision Metal Cutting in 2023

-

How to Choose the Right Plasma Cutting Table for Your Needs?