2025 How to Choose the Best Small CNC Plasma Cutter for Your Needs

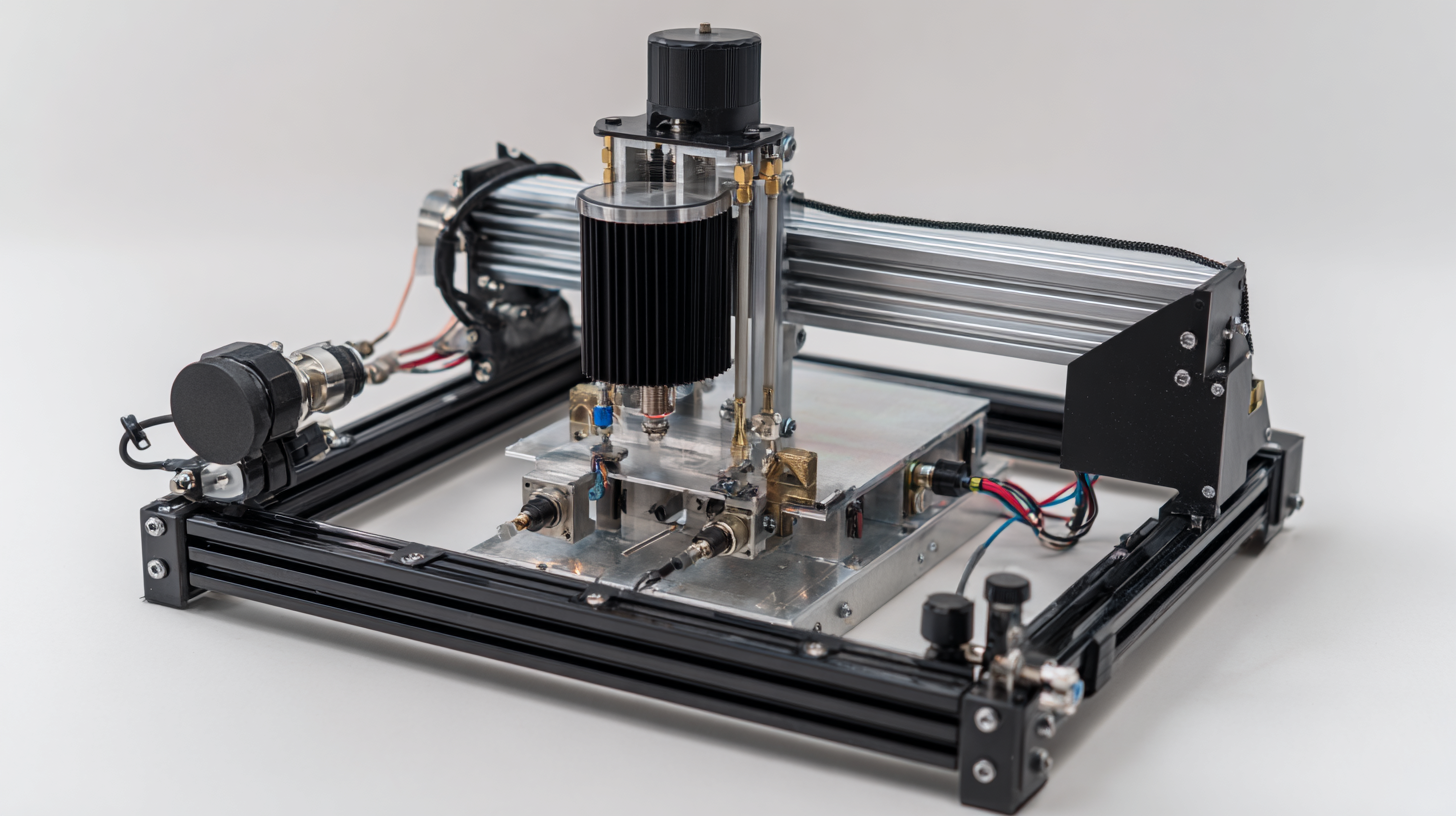

In the rapidly evolving world of metal fabrication, selecting the right equipment is paramount for achieving precision and efficiency. As businesses and hobbyists alike seek to enhance their cutting processes, the demand for small CNC plasma cutters has surged. These versatile machines offer the ideal blend of portability and performance, allowing users to tackle a variety of projects with ease. Industry expert John Smith, a renowned figure in the CNC machining community, emphasizes that "choosing the right small CNC plasma cutter can truly transform your productivity and creativity in metalworking."

Understanding the unique needs of your projects is essential when navigating the myriad options available for small CNC plasma cutters. Factors such as machine size, cutting thickness, and user-friendliness play a crucial role in ensuring that you select the best fit for your specific requirements. With the right knowledge and guidance, you can make an informed decision that not only meets your current demands but also positions you for future growth in your metal fabrication endeavors. As we explore the fundamental aspects of choosing the best small CNC plasma cutter, you'll find valuable insights that will help you achieve success in your projects.

Essential Features to Consider When Selecting a Small CNC Plasma Cutter

When selecting a small CNC plasma cutter, several essential features must be considered to ensure it meets your specific needs. The cutting capacity, measured in thickness and size, is paramount. Consider what materials you'll be working with; different plasma cutters can handle varying thicknesses, which directly affects your efficiency and quality of cut. Additionally, look for a machine with adjustable settings to accommodate different materials and thicknesses.

Another critical feature is the control system of the CNC plasma cutter. An intuitive interface can significantly improve your workflow. Tips for choosing include looking for machines with user-friendly software that allows for easy integration with your design files. Additionally, ensure the cutter has compatibility with both existing and future design platforms you may use, enhancing versatility as your project needs evolve.

Lastly, evaluate the machine's durability and build quality. A robust construction not only ensures longevity but also maintains cutting precision over time. High-quality materials and a solid warranty can be indicators of a reliable investment. Tips for ensuring durability include checking user reviews and test performances, as real-world feedback is invaluable in assessing machine reliability.

Understanding Different Types of Small CNC Plasma Cutters Available in 2025

In 2025, the market for small CNC plasma cutters is expanding significantly, driven by advancements in technology and increasing demand across various industries. The global plasma cutting machine market is anticipated to grow from $699.5 million in 2025 to $905.2 million by 2032, indicating a compound annual growth rate (CAGR) of 3.8%. This growth underlines the importance of understanding the different types of small CNC plasma cutters available in the market, allowing users to tailor their choices to specific needs and applications.

When selecting a small CNC plasma cutter, it is essential to consider the various types available, including handheld models, automated systems, and high-definition options. Each type offers distinct advantages, such as portability, precision, or speed, making them suitable for different tasks, from hobbyist projects to professional fabrication. Additionally, the integration of user-friendly CNC controllers and software, such as those compatible with popular machine setups, enhances the overall cutting experience by simplifying operation and improving efficiency. As the market evolves, understanding these factors will be crucial for users looking to invest in the right equipment for their cutting needs.

2025 Small CNC Plasma Cutters Overview

Comparing Cost vs. Quality: Finding the Right Balance in Small CNC Plasma Cutters

When selecting a small CNC plasma cutter, the balance between cost and quality is crucial. According to a recent industry report by Research and Markets, the global CNC plasma cutting machine market is projected to grow at a CAGR of 5.3% from 2021 to 2026. This growth reflects the increasing demand for precision cutting in various industries, making it imperative for buyers to understand the trade-offs involved.

Cheaper models might initially seem attractive, but they often compromise on precision, durability, and long-term operational costs.

On the other hand, high-quality CNC plasma cutters can be a significant investment, often starting above $10,000. A study by Grand View Research indicates that while the upfront cost might be steep, quality machines ensure lower maintenance and operational costs over time. This is particularly important for businesses looking to enhance productivity and output quality.

Therefore, investing in a well-reviewed, reliable cutter often leads to cost savings in the long run, emphasizing that finding the right balance between price and performance is essential for maximizing operational efficiency and return on investment.

User-Friendly Software Options for Small CNC Plasma Cutters

When selecting a small CNC plasma cutter, the software that drives the machine plays a pivotal role in achieving high-quality results. User-friendly software options not only simplify the learning curve for beginners but also enhance overall productivity. Look for software that provides intuitive interfaces, drag-and-drop design features, and comprehensive toolpaths that can seamlessly integrate with various CAD programs. This functionality can significantly reduce the time from design conception to actual cutting.

In addition to ease of use, consider software that offers robust support features, such as tutorials, forums, and customer service. A community of users can be invaluable, providing tips and troubleshooting assistance. Additionally, functionality for advanced features like nesting, which maximizes material usage, can be a substantial benefit. Ultimately, the right software will empower you to unlock the full potential of your small CNC plasma cutter, enabling you to create intricate designs with precision and efficiency.

Top Brands and Models to Look Out for in 2025 for Small CNC Plasma Cutters

When selecting the best small CNC plasma cutter for your needs in 2025, it's crucial to consider both the leading brands and cutting-edge models available on the market. Advanced CNC plasma cutting technology is becoming increasingly accessible, catering to a variety of applications ranging from artistic metalwork to industrial fabrication. In this evolving landscape, look for models that offer versatility in cutting thickness and speed, as they are essential for maximizing productivity and efficiency.

In 2025, several top brands are set to dominate the small CNC plasma cutter market. These brands are focusing on innovation, user-friendly interfaces, and enhanced safety features, making it easier for beginners and seasoned professionals alike to operate their machines effectively. Additionally, trends suggest that more compact design options will be prevalent, allowing users to save workspace while still achieving high performance. As you navigate your choices this year, pay close attention to customer reviews and expert evaluations to ensure you invest in a model that aligns with your specific requirements and business goals.

2025 How to Choose the Best Small CNC Plasma Cutter for Your Needs

| Model | Cutting Thickness (Steel) | Cutting Speed (IPM) | Power Source | Weight | Price Range |

|---|---|---|---|---|---|

| Model A | 1/2 inch | 50 IPM | 240V AC | 63 lbs | $900 - $1200 |

| Model B | 3/8 inch | 40 IPM | 120V AC | 55 lbs | $700 - $1000 |

| Model C | 1/4 inch | 60 IPM | 240V AC | 50 lbs | $800 - $1100 |

| Model D | 1 inch | 30 IPM | 240V AC | 70 lbs | $1200 - $1500 |

| Model E | 5/8 inch | 45 IPM | 120V AC | 58 lbs | $950 - $1300 |

Related Posts

-

Understanding the Specifications of the Best Industrial CNC Plasma Table and How to Use It

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success

-

Ultimate Guide to Selecting the Best Industrial CNC Plasma Table for Your Business

-

Discover Premier CNC Plasma Cutting Solutions from Leading Chinese Manufacturers for Global Markets

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

What is the Future of the Best Small CNC Plasma Tables in Global Manufacturing?