The Future of Precision Crafting with Innovative Table CNC Machines

As industries continue to evolve with technological advancements, the focus on precision crafting has reached new heights, driven significantly by the rise of table CNC machines. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to grow from $68.4 billion in 2022 to $98.3 billion by 2027, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth is fueled by the increasing demand for high-quality craftsmanship across various sectors, including woodworking, metalworking, and prototyping. Table CNC machines, known for their compact design and versatility, have emerged as crucial tools for both small workshops and large manufacturing plants. They facilitate intricate designs and enhance production efficiency, making them essential in the drive for innovation in precision crafting. As we delve deeper into the future of table CNC technology, it is important to explore how these machines are redefining the manufacturing landscape and revolutionizing the art of crafting with unparalleled accuracy.

The Evolution of CNC Technology in Precision Crafting

The evolution of CNC (Computer Numerical Control) technology has significantly transformed the landscape of precision crafting. Initially, CNC machines were primarily limited to basic operations, such as milling and drilling, with limited complexity and flexibility. However, advancements in software and machine design have allowed for greater precision, enabling artisans and manufacturers to achieve intricate and finely detailed work that was previously difficult or impossible to accomplish. This shift has made CNC machines indispensable tools in various industries, from woodworking to metal fabrication.

The evolution of CNC (Computer Numerical Control) technology has significantly transformed the landscape of precision crafting. Initially, CNC machines were primarily limited to basic operations, such as milling and drilling, with limited complexity and flexibility. However, advancements in software and machine design have allowed for greater precision, enabling artisans and manufacturers to achieve intricate and finely detailed work that was previously difficult or impossible to accomplish. This shift has made CNC machines indispensable tools in various industries, from woodworking to metal fabrication.

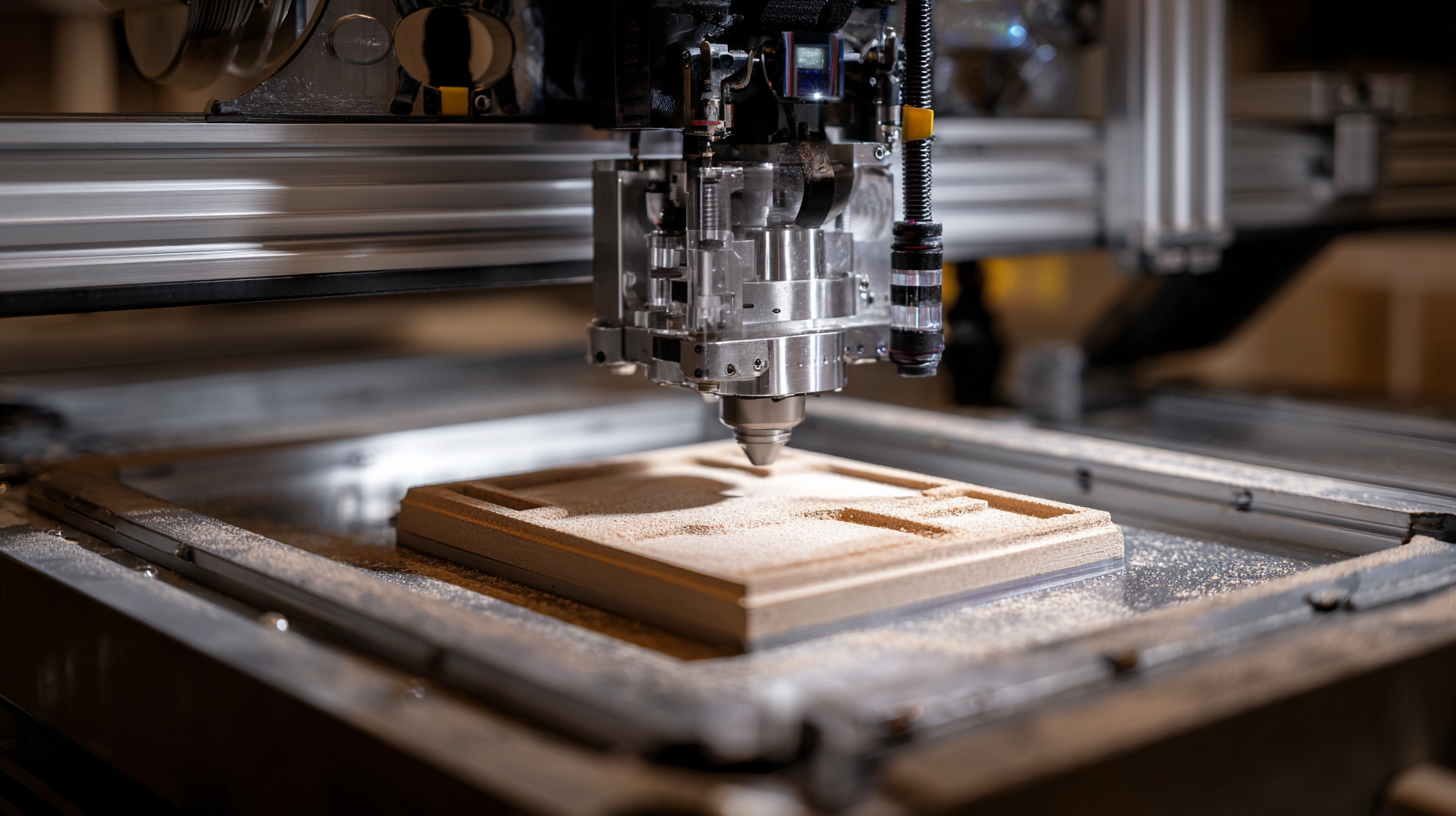

Moreover, the introduction of innovative table CNC machines has further enhanced the possibilities for precision crafting. These machines are designed to occupy smaller workspaces while maintaining high performance, making them accessible for small workshops and hobbyists. With features such as increased speed, enhanced user interfaces, and compatibility with a wider range of materials, modern CNC technology allows creators to execute their visions with unmatched accuracy. As a result, the craft of precision making has entered a new era, where creativity can flourish alongside technological innovation.

Key Features of Innovative Table CNC Machines

Innovative table CNC machines are revolutionizing the world of precision crafting, offering features that enhance both performance and user experience. One of the key features is their advanced control systems, which utilize intuitive software that allows users to create complex designs with ease. These machines often come equipped with touch-screen interfaces that simplify navigation and provide real-time feedback, making them accessible to both beginners and experienced craftsmen.

Another significant aspect of innovative table CNC machines is their versatility. Many models offer interchangeable tooling options, allowing craftsmen to seamlessly switch between cutting, engraving, and milling tasks. This adaptability enables users to tackle a variety of projects, whether working with wood, plastics, or metal. Additionally, the compact design of these machines makes them suitable for small workshops or home environments, further broadening their appeal and usability in the precision crafting landscape.

Applications of Table CNC Machines in Various Industries

Table CNC machines are revolutionizing multiple industries by providing precision and efficiency in crafting various products. In woodworking, these machines allow artisans to create intricate designs and customized furniture with ease, reducing manual errors and increasing productivity. The ability to program detailed specifications means that even the most complex patterns can be reproduced consistently, catering to the rising demand for personalized pieces in residential and commercial spaces.

In the metalworking sector, table CNC machines are equally impactful, facilitating the manufacturing of precision components for automotive and aerospace applications. These machines can handle various materials, including aluminum and steel, enabling the production of lightweight yet durable parts. Furthermore, the integration of advanced software technology allows for real-time adjustments and monitoring, ensuring that quality and specifications are met throughout the production cycle. Overall, the versatility and accuracy of table CNC machines make them indispensable tools across diverse fields, driving innovation and efficiency in crafting processes.

The Future of Precision Crafting with Innovative Table CNC Machines

This bar chart showcases the applications of Table CNC Machines across various industries, illustrating their growing significance in manufacturing, woodworking, metalworking, and prototyping. The data reflects the percentage of industry adoption for CNC machines in 2023.

Benefits of Precision Crafting with Advanced CNC Solutions

The emergence of advanced CNC solutions has revolutionized the landscape of precision crafting, providing artisans and manufacturers with the tools necessary to create intricate designs with unparalleled accuracy. One of the most significant benefits of utilizing innovative table CNC machines is their ability to execute complex cuts and shapes that would be nearly impossible to achieve by hand. This precision not only enhances the aesthetic quality of crafts but also ensures consistency across batches, leading to higher quality outputs and reduced material waste.

Moreover, the automation offered by these machines streamlines the crafting process, significantly reducing production time. With user-friendly interfaces and programmable settings, even those with minimal technical skills can produce high-quality results. This democratization of precision crafting widens the scope for creativity, enabling hobbyists and professionals alike to experiment with new designs and materials without the fear of costly errors. As the technology continues to advance, the future of precision crafting will undoubtedly be defined by the capabilities of innovative table CNC machines, making them indispensable tools in the modern workshop.

The Future of Precision Crafting with Innovative Table CNC Machines

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| High Precision Cutting | CNC machines can achieve high tolerances, ensuring accurate cuts and details. | Reduces material waste and improves quality of output. | Woodworking, Metal Fabrication |

| Automation and Efficiency | CNC operations can be automated, reducing the need for manual labor. | Increases production speed and lower labor costs. | Manufacturing, Prototyping |

| Versatility | Able to work with various materials including wood, metal, plastic, and composites. | Allows for a broader range of products to be created. | Custom Metal Parts, Decorative Wood Items |

| Customizability | CNC software can easily modify designs to meet specific customer needs. | Enhances customer satisfaction with personalized products. | Custom Furniture, Personalized Gifts |

| Safety Features | Modern CNC machines are equipped with safety mechanisms to protect operators. | Minimizes workplace accidents and enhances operator safety. | Metalworking, Industrial Production |

Future Trends in CNC Technology and Crafting Techniques

The evolution of CNC technology is rapidly transforming the landscape of crafting and manufacturing. As we look to the future, significant trends are emerging that will shape the way artisans and engineers create intricate designs. One such trend is the integration of artificial intelligence and machine learning into CNC machines. These advancements enable machines to adaptively learn from their previous operations, resulting in enhanced precision and efficiency. By automating complex processes, makers can focus more on creativity rather than manual adjustments, leading to innovative outcomes and improved craftsmanship.

Another prominent trend is the rise of hybrid manufacturing techniques that combine additive and subtractive processes. This approach allows for greater flexibility in design and the ability to create complex geometries that were once difficult to achieve. As table CNC machines become more sophisticated, they are increasingly equipped with features that accommodate both milling and 3D printing capabilities. This fusion not only broadens the potential applications but also encourages a new generation of creators to experiment with diverse materials and techniques, pushing the boundaries of traditional crafting. The future therefore holds immense potential for those willing to embrace the advancements in CNC technology.

Related Posts

-

Understanding the Benefits of Table CNC Machines for Modern Manufacturing

-

Exploring Innovative Alternatives to the Best Cutting Table for Your Workshop

-

How to Choose the Best Small CNC Plasma Cutting Machine for Your Business Needs

-

7 Compelling Reasons Why the Best Plasma Table Will Transform Your Production Line

-

7 Best Industrial CNC Machines Revolutionizing Precision Manufacturing Today

-

The Future of Precision with CNC Plasma Cutting Tables in Manufacturing