Exploring the Future of Precision: The Evolution of Small CNC Plasma Cutting Machines

In recent years, the manufacturing sector has witnessed a significant transformation with the advent of advanced technologies. Among these innovations, the small CNC plasma cutting machine has gained traction as a preferred choice for many industries, owing to its precision, efficiency, and compact design. According to a report by MarketsandMarkets, the global CNC cutting machine market is expected to reach $5.89 billion by 2027, growing at a CAGR of 6.5% from 2020. This burgeoning demand is driven by the need for high-quality cutting solutions that can enhance production processes across various sectors, including automotive, aerospace, and metal fabrication. As manufacturers strive to maintain competitiveness in a rapidly evolving global market, small CNC plasma cutting machines are not only redefining cutting capabilities but also setting the stage for future advancements in manufacturing technology.

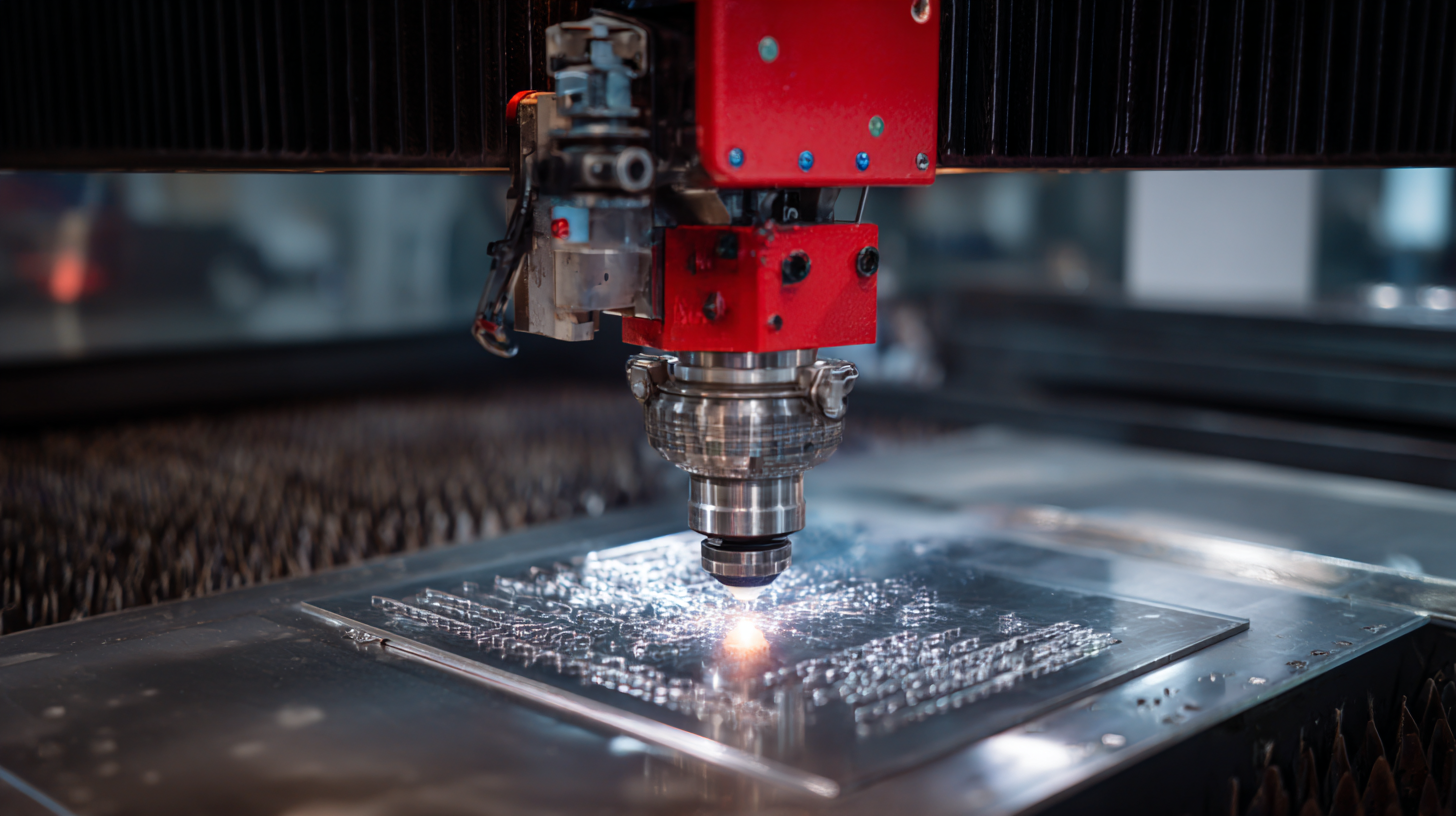

The Advancements in CNC Plasma Cutting Technology

The CNC plasma cutting technology has significantly advanced in recent years, improving not only efficiency but also precision in various industrial applications. According to a report by MarketsandMarkets, the CNC plasma cutting market is projected to reach $7.67 billion by 2026, growing at a CAGR of 6.8%. This surge is largely attributed to the demand for precise and efficient cutting solutions in industries such as manufacturing, automotive, and aerospace. The evolution of small CNC plasma cutting machines has been particularly noteworthy, with newer models offering enhanced portability and user-friendly interfaces, making them accessible for smaller enterprises.

The CNC plasma cutting technology has significantly advanced in recent years, improving not only efficiency but also precision in various industrial applications. According to a report by MarketsandMarkets, the CNC plasma cutting market is projected to reach $7.67 billion by 2026, growing at a CAGR of 6.8%. This surge is largely attributed to the demand for precise and efficient cutting solutions in industries such as manufacturing, automotive, and aerospace. The evolution of small CNC plasma cutting machines has been particularly noteworthy, with newer models offering enhanced portability and user-friendly interfaces, making them accessible for smaller enterprises.

Tip: When selecting a CNC plasma cutting machine, consider the material types and thicknesses you plan to work with. This ensures the machine you choose will meet your specific cutting requirements and improve your overall workflow.

Recent advancements have also incorporated automation and software integration, enabling manufacturers to program complex cuts with minimal manual intervention. For instance, the introduction of advanced CAM (Computer-Aided Manufacturing) software allows for quicker design modifications, enhancing productivity. As these technologies evolve, the potential for small CNC plasma cutters to offer more versatile applications increases significantly, providing businesses with innovative solutions to stay competitive.

Tip: Regular maintenance of your CNC plasma cutting machine is crucial for sustaining performance. Schedule routine checks and keep software updated to prolong the lifespan of your equipment and minimize downtime.

Key Features of Modern Small CNC Plasma Cutting Machines

The landscape of small CNC plasma cutting machines is rapidly evolving, marked by innovative features that enhance precision and efficiency. Modern machines now integrate advanced technologies such as AI and automation, catering to the rising demand for high-precision applications. According to market analysis, the CNC machine tools market is projected to grow by USD 21.9 billion from 2025 to 2029, reflecting a strong push towards multi-axis machining centers. This growth is driven by industries seeking to improve production capabilities and reduce operational costs.

Key features of today's small CNC plasma cutting machines include enhanced control systems that allow for better path planning and reduced material waste. These machines now come equipped with user-friendly interfaces and robust software that facilitate quick setup and programming. Moreover, as seen in recent market trends, manufacturers are extending warranties on their products, indicating confidence in their durability and reliability.

Tip: When selecting a small CNC plasma cutting machine, consider models that offer integrated software solutions for easier operation and maintenance. Another important factor is the machine's cutting speed and precision—look for specifications that align with your project requirements to ensure optimal performance.

Applications of Small CNC Plasma Cutters in Various Industries

The evolution of small CNC plasma cutting machines has significantly transformed their applications across various industries. This technology, renowned for its precision and efficiency, is becoming integral in sectors like automotive, aerospace, and construction. The CNC machine market is projected to be worth approximately $77 billion by 2024, growing at a compound annual growth rate (CAGR) of 5.5%. Small CNC plasma cutters stand out in this growth due to their versatility and ability to produce intricate designs with minimal material waste.

Moreover, the sawing and cutting tools market is experiencing robust expansion, with an estimated valuation of USD 38.2 billion in 2025. As industries increasingly leverage automation, the demand for CNC plasma cutters is expected to rise. Notably, these machines are not just limited to metal cutting; their applications extend to various materials, making them a preferred choice for manufacturers looking to optimize production processes and enhance product quality. As innovation continues to drive this industry forward, small CNC plasma cutting machines are set to play a crucial role in shaping the future of manufacturing.

Exploring the Future of Precision: The Evolution of Small CNC Plasma Cutting Machines

| Industry | Application | Machine Specs | Cutting Thickness (mm) | Typical Material |

|---|---|---|---|---|

| Automotive | Prototype Parts | Compact, portable, 30A plasma cutter | 1-10 | Steel, Aluminum |

| Construction | Structural Cutouts | High-precision cutter, 45A output | 2-12 | Mild Steel |

| Aerospace | Fuselage Components | Precision CNC with water cooling | 1-5 | Titanium, Aluminum |

| Arts & Crafts | Custom Decor | Small desktop CNC plasma system | 0.5-6 | Metal Sheets, Copper |

| Manufacturing | Production Parts | Industrial-grade plasma cutter | 3-15 | Stainless Steel |

Comparative Analysis: Traditional vs. Precision CNC Plasma Cutting

As industries continue to evolve, the shift from traditional to precision CNC plasma cutting machines is becoming increasingly evident. Traditional CNC plasma cutting systems have been staples in metal fabrication for years, characterized by their reliability but often limited in accuracy. Recent industry reports indicate that precision CNC plasma machines can achieve cuts with tolerances as fine as ±0.5 mm, a significant improvement over their traditional counterparts, which typically operate at ±1.5 mm or worse. This leap in precision opens up new horizons for applications requiring complex geometries and tighter tolerances, making such machines indispensable in sectors like aerospace and automotive.

As industries continue to evolve, the shift from traditional to precision CNC plasma cutting machines is becoming increasingly evident. Traditional CNC plasma cutting systems have been staples in metal fabrication for years, characterized by their reliability but often limited in accuracy. Recent industry reports indicate that precision CNC plasma machines can achieve cuts with tolerances as fine as ±0.5 mm, a significant improvement over their traditional counterparts, which typically operate at ±1.5 mm or worse. This leap in precision opens up new horizons for applications requiring complex geometries and tighter tolerances, making such machines indispensable in sectors like aerospace and automotive.

When selecting a CNC plasma cutting machine, consider the material and thickness you will be working with. Thinner materials often benefit from precision cutting methods that minimize the heat-affected zone. For instance, if you're cutting stainless steel or aluminum, a precision CNC plasma cutter equipped with advanced motion control technology can reduce warping and improve the cut quality significantly.

Tips: Always evaluate the software capabilities of the CNC plasma machine you plan to purchase. Modern systems come with advanced nesting software that optimizes material usage, potentially saving you up to 15-20% on material costs. Additionally, investing in a model with automated height control can enhance the consistency of cuts, ultimately leading to higher productivity and reduced operational costs.

Future Trends in Small CNC Plasma Cutting Solutions

The small CNC plasma cutting machine market is poised for significant growth, driven by the rising demand for high-precision cutting solutions across various industries. Recent analysis indicates that the CNC machine tools market is expected to expand by USD 21.9 billion between 2025 and 2029, largely due to the increasing implementation of AI technologies. This evolution not only enhances efficiency but also allows for more accurate and complex designs, reinforcing the role of CNC plasma cutters in modern manufacturing.

Furthermore, the overall metal processing machine industry is projected to grow from USD 94.52 billion in 2023 to USD 120.0 billion by 2032. The increasing need for automated solutions in metalworking is shaping future trends, as small CNC plasma cutting machines offer a compact, versatile, and cost-effective alternative to larger systems. With advancements in technology and a shift towards automation, these machines are likely to become integral to the production processes, optimizing not only precision but also operational efficiency in various applications.