Emerging Trends for 2025: The Rise of Best CNC Plasma Cutting Tables in Manufacturing Efficiency

As we advance towards 2025, the manufacturing landscape is undergoing significant transformations, particularly with the adoption of advanced technologies like the CNC plasma cutting table. According to a report by Market Research Future, the global CNC plasma cutting machine market is projected to reach USD 4 billion by 2025, driven by the demand for improved precision and efficiency in metal fabrication. Industries are increasingly recognizing the benefits of integrating these cutting-edge machines into their operations, allowing for enhanced productivity and reduced operational costs.

This blog will explore the emerging trends and innovations in CNC plasma cutting technology that are poised to revolutionize manufacturing processes, setting new standards for efficiency and reliability. With insights drawn from industry reports and expert analysis, we will delve into the factors that are driving the rise of CNC plasma cutting tables and their pivotal role in shaping the future of manufacturing.

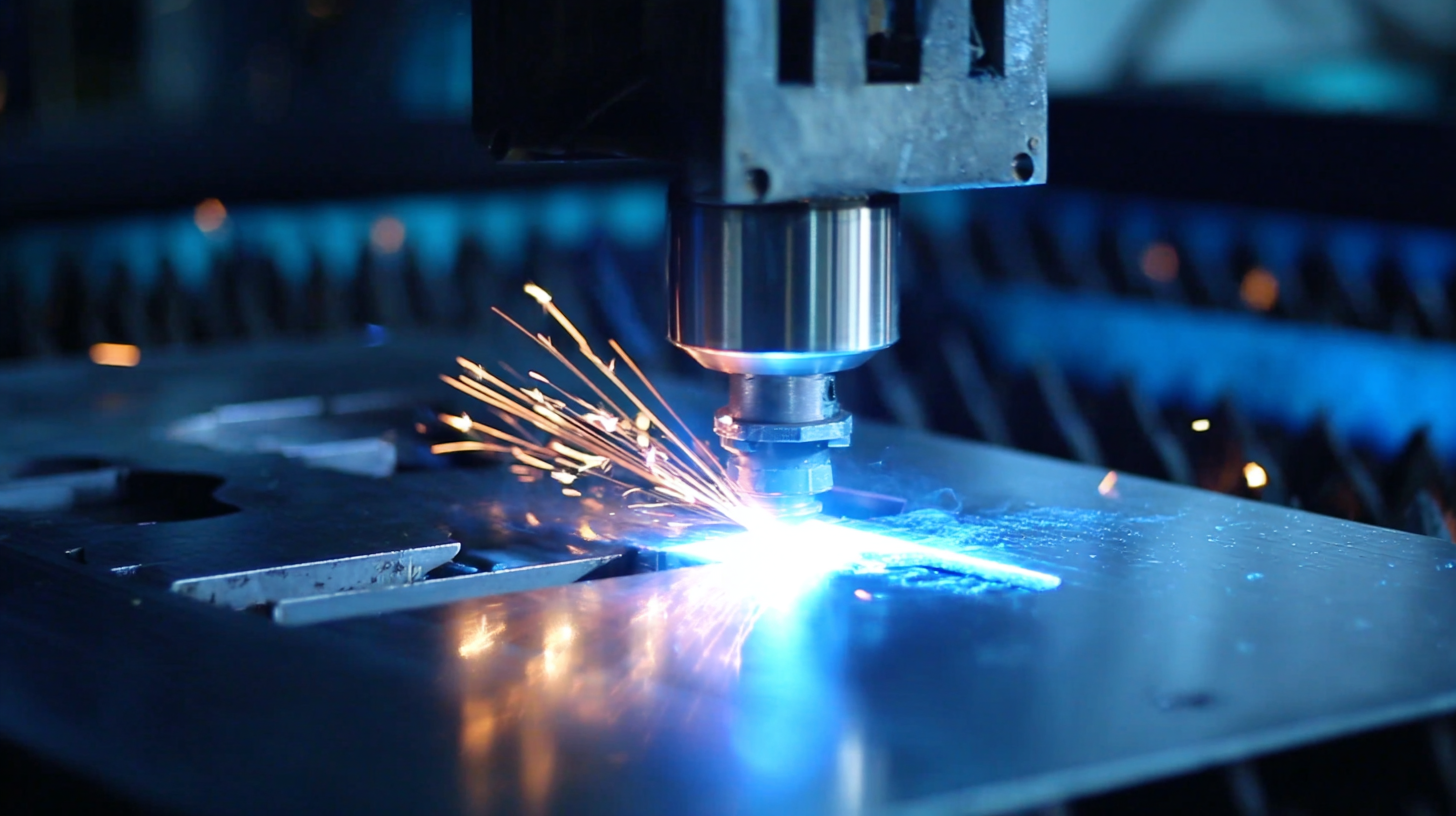

The Evolution of CNC Plasma Cutting Technology and Its Impact on Manufacturing

The evolution of CNC plasma cutting technology is revolutionizing the manufacturing sector, leading to enhanced productivity and precision. As per a recent report by MarketsandMarkets, the CNC plasma cutting market is expected to grow from $3.4 billion in 2020 to $4.9 billion by 2025, reflecting a CAGR of 7.1%. This growth is driven by advancements in software integration and automation, allowing manufacturers to achieve intricate designs with minimal human input. The emergence of intelligent CNC systems not only streamlines operations but also reduces material waste, translating to significant cost savings.

To harness the full potential of CNC plasma cutting, manufacturers can implement a few key strategies. First, adopting the latest software solutions enables real-time monitoring and optimization of cutting processes, ensuring higher efficiency. Second, regular maintenance of cutting equipment is crucial; a well-maintained machine can achieve cutting tolerances of up to ±0.5 mm, vastly improving the quality of end products.

Moreover, investing in operator training can significantly enhance production outcomes. Skilled operators can adjust settings according to material types and thicknesses, ensuring optimal cutting speeds and reduced setup times. By leveraging these strategies, companies can position themselves at the forefront of manufacturing innovation while maximizing their investment in CNC plasma technology.

Emerging Trends for 2025: The Rise of Best CNC Plasma Cutting Tables in Manufacturing Efficiency

| Feature | 2023 | 2025 | Impact on Manufacturing |

|---|---|---|---|

| Cutting Speed (ipm) | 200 | 350 | Increased productivity and reduced lead times. |

| Precision (tolerance) | ±0.5 mm | ±0.2 mm | Higher accuracy leading to better fit and finish of components. |

| Software Integration | Basic CAD/CAM | Advanced AI-driven software | Streamlined design to production processes, enhancing creativity. |

| Energy Consumption | 20 kWh | 15 kWh | Cost savings through reduced energy bills and improved sustainability. |

| Material Versatility | Mild Steel | Mild Steel, Stainless Steel, Aluminum | Expanded market opportunities by processing a wider range of materials. |

Key Features to Consider When Selecting the Best CNC Plasma Cutting Tables

The manufacturing sector is experiencing a notable shift towards efficiency and precision, particularly with the increasing adoption of CNC plasma cutting tables. As highlighted by recent market analysis, the global CNC machine market is projected to expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, demonstrating a compound annual growth rate of 9.9%. This growth is reflective of manufacturers' need for greater operational efficiency and cost reduction, as illustrated by case studies like that of a bicycle manufacturer, which improved output by 20% while significantly reducing downtime and costs.

When selecting the best CNC plasma cutting tables, key features must be carefully considered. Factors such as precision, versatility, and ease of integration with existing systems are crucial in optimizing production processes. Additionally, the ability to leverage digital technology for real-time order tracking and flexible scheduling can transform traditional manufacturing methods. With such advancements, companies can expect not only to enhance productivity but also to better meet the demands of a rapidly evolving market landscape.

Comparative Analysis of Top CNC Plasma Cutting Machines for 2025

As we approach 2025, the competitive landscape of the CNC plasma cutting machines market is evolving, driven by advancements in technology and manufacturing efficiency. With a market size expected to reach USD 673.2 million and a projected growth rate of over 5.1% from 2025 to 2034, manufacturers are increasingly turning to cutting-edge CNC plasma cutting tables to enhance precision and productivity. These machines are not only streamlining production processes but also ensuring greater accuracy in intricate cutting tasks, setting a new standard in the industry.

A comparative analysis of the top CNC plasma cutting machines reveals that key players are integrating innovative features that cater to the dynamic needs of modern manufacturing. From user-friendly interfaces to improved energy efficiency, these machines are designed to optimize workflow and reduce operational costs.

As China emerges as a leader in advanced manufacturing technologies, the focus on high-quality CNC plasma cutting solutions will be paramount for companies aiming to maintain a competitive edge in the global market. This shift underscores the critical importance of evaluating the best machines available in 2025 to leverage the latest advancements and improve overall manufacturing efficiency.

Efficiency Metrics: How CNC Plasma Cutters Enhance Production Speed and Accuracy

The manufacturing landscape is evolving rapidly, and one key aspect driving this change is the integration of CNC plasma cutting machines. As industries strive for greater efficiency, these advanced machines are setting new standards in production speed and accuracy. By utilizing computer numerical control technology, CNC plasma cutters automate the cutting process, significantly reducing the time required to produce intricate parts compared to traditional methods. This automation not only speeds up production but also minimizes human error, ensuring precise measurements and consistent quality.

Moreover, the efficiency metrics associated with CNC plasma cutting are unparalleled. The ability to measure kerf width, surface roughness (Ra), and heat-affected zones (HAZ) accurately allows manufacturers to fine-tune their processes. With the metal processing machine market expected to grow from $94.52 billion in 2023 to $120 billion by 2032, the emphasis on enhancing production capabilities through is becoming clearer. As companies embrace CNC plasma cutting, they position themselves to meet rising demands while maintaining competitive edge in accuracy and production efficiency.

Cost vs. Performance: Evaluating ROI of Investment in CNC Plasma Cutting Technology

As manufacturing technology rapidly evolves, the decision to invest in CNC plasma cutting systems often hinges on a critical analysis of cost versus performance. Evaluating the return on investment (ROI) for CNC plasma cutting technology requires a comprehensive understanding of both initial purchase price and long-term operational efficiencies. Businesses must consider factors such as reduced material waste, enhanced cutting precision, and increased throughput, which all contribute to a favorable ROI over time.

Performance metrics, including speed and accuracy, play a significant role in assessing the effectiveness of CNC plasma cutting tables. These advanced systems offer capabilities that can dramatically improve productivity by minimizing production cycle times and allowing for quicker adaptation to design changes. Additionally, integrating automation with CNC technology can lead to greater reliability and consistency in production quality, further justifying the investment. As companies weigh their options, a careful evaluation of how these machines enhance overall manufacturing efficiency will be crucial to making an informed decision.