CNC Plasma Table Tips for Beginners How to Choose the Right One?

Choosing the right CNC plasma table can be overwhelming for beginners. There are numerous options, each with different features and specifications. Industry expert John Adams, a prominent figure in CNC technology, once said, "Selecting the right plasma table can make or break your project."

This statement rings true for many newcomers in the field. When you start, the choices appear endless. Understanding what you need is crucial. Do you require portability or a larger work area? These decisions often dictate the efficiency of your projects. Visualizing your workspace helps too. Imagine the arrangement and equipment layout that best suits your needs.

Mistakes in selection can lead to frustration. A common issue is purchasing a table that lacks necessary features. Reflecting on your requirements can guide your choice. Each CNC plasma table has unique capabilities. Knowing the key features that align with your goals can lead to better outcomes. Don't rush the process; take time to evaluate different models before making a final decision.

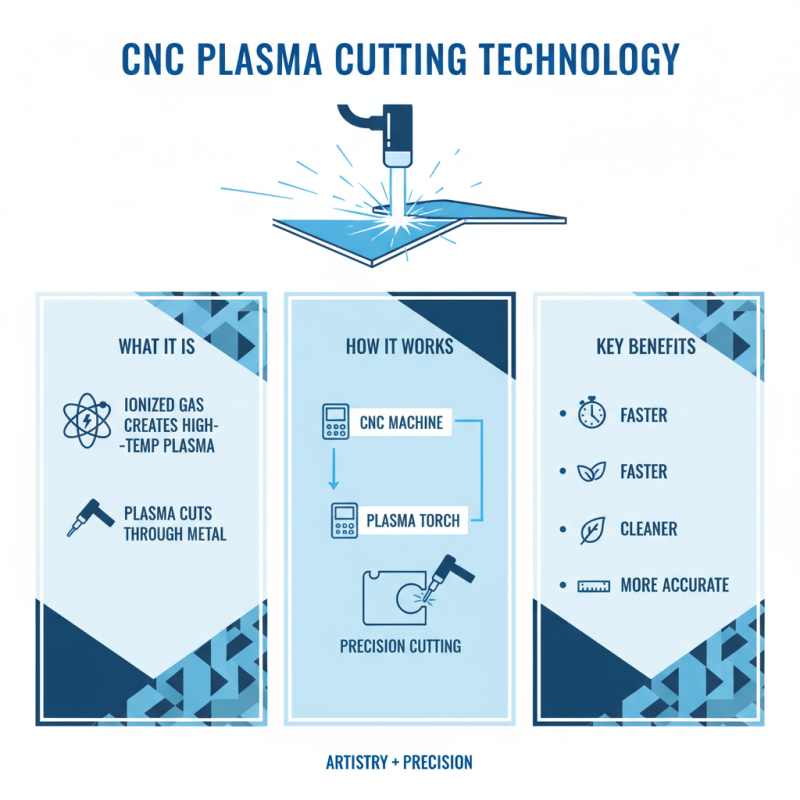

Understanding the Basics of CNC Plasma Cutting Technology

CNC plasma cutting technology is a fascinating field that combines artistry and precision. At its core, plasma cutting uses an ionized gas to create high-temperature plasma. This plasma can cut through metal with stunning accuracy. It's a cleaner, faster alternative to traditional cutting methods.

When exploring CNC plasma tables, it's crucial to understand their components. The gantry system, for instance, holds the torch in place. This system must be robust for stable cutting. Software plays a significant role too. Beginner-friendly interfaces can ease the learning curve. However, complexity in software might lead to user frustration at first.

Setting up the machine requires attention to detail. Ensuring the work surface is level is key. Many beginners overlook this step. A flat surface leads to better cuts and fewer mistakes. Calibration of the torch height also matters. If set incorrectly, it can cause uneven cutting. Embracing the learning process can result in beautiful creations.

Key Features to Consider When Choosing a CNC Plasma Table

When selecting a CNC plasma table, key features determine your success. One essential aspect is the cutting area size. A larger workspace allows flexibility for various projects. Most users need a cutting area of at least 4x4 feet. However, tables with a 5x10 feet area are becoming increasingly popular.

Another vital feature is the torch height controller. This technology enhances precision during cuts. Reports indicate that 70% of professionals prefer tables equipped with automatic height control. It ensures consistent cutting quality, minimizing errors. Yet, it can add to initial costs, so weigh the value against your budget.

Additionally, consider the software compatibility. User-friendly software simplifies design and boosts productivity. Compatibility with existing design tools is crucial. Some tables offer proprietary software that may limit your choices. A clear understanding of your needs will help prevent future headaches. The learning curve for new software can be steep. Many beginners struggle with navigation. Balancing advanced features with usability is crucial for a smooth experience.

CNC Plasma Table Tips for Beginners - Key Features to Consider When Choosing a CNC Plasma Table

| Feature | Description | Importance Level |

|---|---|---|

| Cutting Area Size | The maximum dimensions of the material you can cut. | High |

| Material Compatibility | Types of materials the CNC plasma table can cut (e.g., steel, aluminum). | Medium |

| Power Source | The type of power source used, such as single-phase or three-phase. | High |

| Software Compatibility | Software that works with the CNC for design and operation. | High |

| Precision | The accuracy of the cuts the machine can achieve. | High |

| Budget | Total cost of the CNC plasma table and maintenance. | Medium |

| Customer Support | Availability and quality of support after purchase. | Medium |

Assessing Your Project Needs: Size and Material Requirements

Choosing the right CNC plasma table starts with understanding your project needs. Assess the size of your projects. Will you be working on large pieces or smaller components? A table that is too small will limit your creativity. If you choose a larger model, space becomes an issue in your workspace. Measure twice, cut once!

Material requirements are essential. Different materials need different settings. Aluminum, steel, and stainless steel all have unique properties. Beginners might struggle with settings and feed rates. It’s crucial to experiment and note your findings. Adjusting settings for new materials can lead to frustration.

Consider the thickness of the materials, too. Thicker materials require more powerful machines. However, this might not be suitable for all types of projects. Look into the specifications of each potential table. The right balance is key. It’s about finding what suits you best, even if it takes time. Don’t rush your decision; reflection is essential.

Evaluating Budget Options: Cost vs. Features in CNC Plasma Tables

When evaluating budget options for CNC plasma tables, it’s essential to consider both cost and features. Many beginners might assume that a lower price point means fewer capabilities. However, this isn’t always true. Some budget-friendly tables offer surprising features. It's crucial to identify your specific needs before selecting a model. Are you focusing on precision cuts or speed? This clarity will help differentiate between options.

Not all inexpensive tables perform poorly. Many might lack extras like advanced software. Yet, they can still deliver quality results for small projects. Ask yourself if these additional features justify the price. Keep in mind that investing in a more expensive table doesn’t guarantee perfect performance. Features can sometimes overwhelm new users. Be prepared to learn and experiment. Think about the longevity of the machine as well. A cheaper option might need frequent replacements. Reflect on how often you plan to use the table. It might be wise to spend a bit more for durability, leading to better value over time.

CNC Plasma Tables: Cost vs. Features

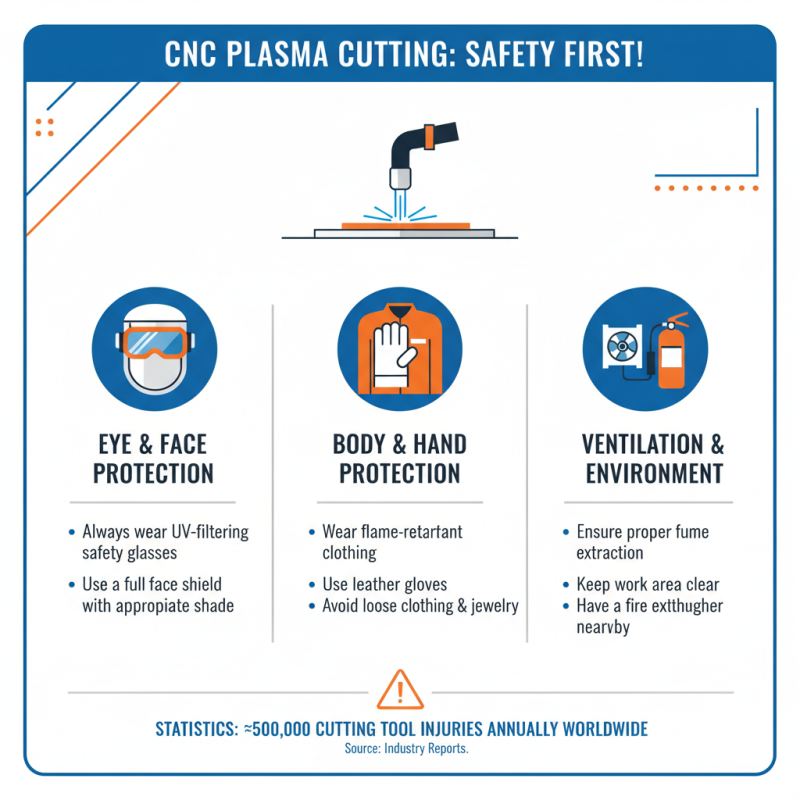

Safety Considerations for Operating CNC Plasma Cutting Machines

Operating a CNC plasma cutting machine can be an exciting venture, but safety must always come first. According to industry reports, around 500,000 injuries occur annually due to improper handling of cutting tools worldwide. Therefore, understanding essential safety considerations is vital for beginners.

Always wear personal protective equipment (PPE) like gloves, goggles, and flame-resistant clothing. The intense heat from plasma cutting can cause serious burns. Furthermore, ensure the workspace is well-ventilated. Inhalation of fumes can lead to respiratory issues. Statistics show that more than 20% of workers in the manufacturing sector report respiratory illnesses related to poor air quality.

Additionally, remember to keep flammable materials far from the machine. A small spark can ignite a fire, leading to extensive damage. It’s alarming that roughly 30% of all workshop fires are linked to metalwork activities. Regularly inspect equipment to avoid malfunction. A faulty machine can endanger operators and bystanders alike. Taking the time to understand these safety measures can significantly reduce risks and provide a more productive working environment.

Related Posts

-

Discover Premier CNC Plasma Cutting Solutions from Leading Chinese Manufacturers for Global Markets

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success

-

7 Best HD Plasma Cutters for Precision Metal Cutting in 2023

-

What is CNC Plasma Cutting and How Does it Work for Beginners

-

2025 How to Master Plasma Cutting: Tips, Techniques, and Best Practices