Maximize Efficiency: How CNC Plasma Cutting Tables Are Revolutionizing Metal Fabrication in 2023

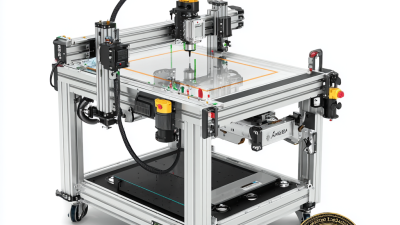

In the fast-evolving landscape of metal fabrication, the CNC plasma cutting table stands out as a transformative technology redefining efficiency and precision. With its remarkable ability to cut through various materials with incredible speed and accuracy, this innovative tool is quickly becoming a staple in workshops around the globe. Jason Becker, a noted expert in automation technology and the founder of Precision Cut Solutions, emphasizes the impact of this technology by stating, “CNC plasma cutting tables are not just tools; they are essential game-changers in modern metal processing.”

As we delve into the significance of CNC plasma cutting tables in 2023, it becomes evident that the integration of this advanced machinery directly correlates to increased productivity and reduced operational costs. Fabricators are now able to produce intricate designs that were once thought to be impossible, all while maintaining a level of consistency that ensures high-quality output. The synergy of software advancements with these cutting-edge tables enables users to streamline their workflow, reducing manual labor and increasing throughput.

Furthermore, the adaptability of CNC plasma cutting tables makes them suitable for a wide range of applications, from automotive to construction. Their efficiency not only meets the demands of current industry standards but also paves the way for future innovations in metal fabrication techniques. As we explore the revolutionizing potential of CNC plasma cutting tables, we gain insight into how they will shape the future of manufacturing processes for years to come.

The Evolution of CNC Plasma Cutting Technology in 2023

In 2023, the evolution of CNC plasma cutting technology has marked a significant shift in the metal fabrication industry. With enhanced software solutions, cutting-edge plasma generators, and improved material handling systems, manufacturers are now equipped with tools that greatly increase precision and reduce production time. The integration of AI and machine learning algorithms has further optimized cutting paths and minimized waste, allowing for a more efficient workflow that meets the demands of modern production.

Additionally, advancements in the user interface of CNC plasma cutting tables have streamlined the operation process, enabling operators to easily program complex cuts with minimal training. The introduction of 3D cutting capabilities and adaptive power control has allowed for greater versatility in handling various materials and thicknesses. As a result, businesses can now tackle diverse projects, from artistic metalwork to industrial applications, with unprecedented speed and accuracy. This evolution is not just transforming efficiency; it’s redefining what’s possible in metal fabrication.

Key Advantages of Using CNC Plasma Cutting Tables for Metal Fabrication

CNC plasma cutting tables are reshaping the landscape of metal fabrication in 2023, offering significant advantages that enhance efficiency and precision. As industries shift towards automation, the global market for CNC plasma cutting machines is projected to grow substantially, from $707.5 million in 2025 to an impressive $1.163 billion by 2035. This growth reflects a rising demand for advanced manufacturing solutions that can meet the increasing productivity needs of fabricators.

One of the key benefits of using CNC plasma cutting tables is their ability to execute intricate cuts with unparalleled speed and accuracy. Compared to traditional methods, these machines significantly reduce material waste, allowing for cost-effective production. The celebration of ten years in the industry for certain manufacturers highlights the evolution of plasma cutting technology, turning what once was a simple cutting process into a sophisticated manufacturing tool that drives productivity. In addition, the affordability and precision of modern industrial CNC plasma cutters enable more fabricators to adopt this technology, further propelling market expansion and redefining standards in metal fabrication.

Maximize Efficiency: How CNC Plasma Cutting Tables Are Revolutionizing Metal Fabrication in 2023

| Feature | CNC Plasma Cutting Tables | Traditional Cutting Methods |

|---|---|---|

| Cutting Speed | Up to 20 times faster | Slower cutting times |

| Precision | High precision up to ±0.1 mm | Lower precision, more human error |

| Material Versatility | Works with various metals (steel, aluminum, brass) | Limited material usage |

| Operational Costs | Lower long-term costs | Higher ongoing expenses |

| Ease of Use | User-friendly software interfaces | Requires skilled operators |

Top Industries Benefiting from CNC Plasma Cutting Innovations

In 2023, CNC plasma cutting technology is increasingly becoming a game-changer across various industries, particularly in manufacturing, automotive, and garment sectors. The advancements in plasma cutting provide unmatched precision and efficiency, enabling companies to streamline production processes. Reports indicate that the global CNC plasma cutting machine market is projected to reach $5.62 billion by 2027, driven by a demand for speed and accuracy in metal fabrication.

The automotive industry stands at the forefront of this revolution, employing CNC plasma cutting for the fabrication of complex components with quick turnaround times. For instance, tailored solutions for custom truck parts can be achieved effortlessly, with cutting speeds that significantly reduce operational downtime. Additionally, the garment industry is witnessing similar advancements as businesses adopt automated cutting technologies to enhance production capabilities, ultimately resulting in lower costs and faster delivery times. As industries recognize the value of integrating cutting-edge technologies like CNC plasma cutting, the trend of automation will likely continue to thrive, marking a pivotal shift in manufacturing efficiency.

Comparison of CNC Plasma Cutting Tables vs. Traditional Methods

CNC plasma cutting tables represent a significant advancement over traditional metal fabrication methods. While traditional cutting often relies on mechanical saws or torches, CNC technology offers unparalleled precision and speed. The ability to input digital designs directly into the cutting process streamlines production and minimizes waste, ensuring that each cut is consistent and accurate. This shift not only enhances productivity but also allows for more complex designs that were previously difficult to achieve with manual techniques.

When considering a transition from traditional methods to CNC plasma cutting, it’s essential to weigh the advantages against the investment needed. Here are some tips: First, assess the volume of cuts needed. For businesses that require high output, CNC plasma cutting systems can significantly reduce the time spent on each project. Next, ensure that your team is trained to operate the machinery. While CNC machines are user-friendly, proper training maximizes their effectiveness and safety. Lastly, consider the types of materials you plan to cut; CNC plasma cutting is particularly advantageous for thicker metals, where traditional methods may struggle.

Ultimately, the evolution of metal fabrication in 2023 is largely driven by the efficiency, accuracy, and versatility of CNC plasma cutting tables, making them an invaluable asset in modern manufacturing.

Future Trends in CNC Plasma Cutting and Metal Fabrication Strategies

The future of CNC plasma cutting and metal fabrication is set for significant transformation as new technologies and market dynamics reshape the landscape. With the global plasma cutting machine market projected to expand from $699.5 million in 2025 to $905.2 million by 2032, a compound annual growth rate of 3.8% indicates a rising demand for efficiency and precision in manufacturing processes. As industries seek to maximize productivity while navigating disruptions, the implementation of advanced CNC plasma cutting tables has become paramount. These tools not only enhance the speed and accuracy of metal cutting but also allow manufacturers to adapt swiftly to changing market needs.

Moreover, the increasing integration of artificial intelligence within the manufacturing sector will further propel growth in the metal machining market, anticipated to grow by USD 18.43 billion from 2024 to 2028. AI technologies enable predictive maintenance, automate design processes, and refine production workflows, empowering the workforce and fostering agility in operations. As companies recognize the vital role of innovative strategies in their success, the evolution of CNC plasma cutting and metal fabrication will be instrumental in steering the future of manufacturing towards greater resilience and competitive advantage.

Maximize Efficiency: Trends in CNC Plasma Cutting and Metal Fabrication in 2023

Related Posts

-

The Future of Metal Fabrication with Advanced Plasma Cutting Tables

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

What is the Future of the Best Small CNC Plasma Tables in Global Manufacturing?

-

How to Navigate Import and Export Certifications for Best Small Plasma Tables

-

Exploring the Future of Precision: The Evolution of Small CNC Plasma Cutting Machines