What is CNC Plasma Cutting and How Does it Work for Beginners

CNC plasma cutting is a revolutionary technology that has transformed the way metal is processed in various industries. This advanced cutting method utilizes a high-velocity jet of ionized gas, or plasma, to cut through conductive materials with precision and efficiency. For beginners, understanding the fundamental principles of CNC plasma is essential to appreciating its capabilities and applications. In this article, we will delve into the workings of CNC plasma cutting, highlighting its advantages, the components involved, and the processes that make it a preferred choice for metal fabrication.

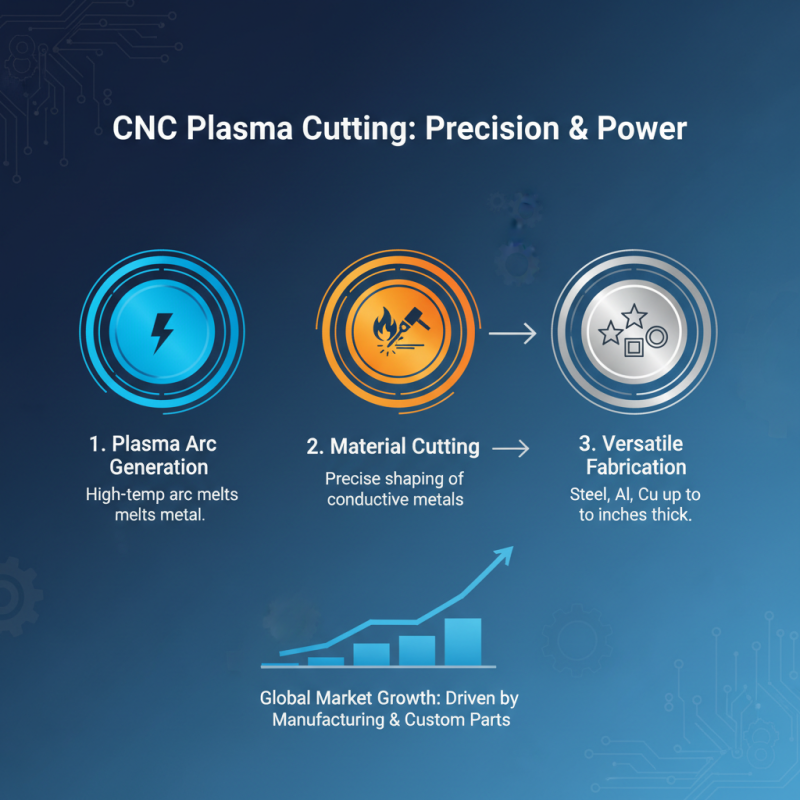

The CNC plasma cutting process begins with the creation of plasma, which is generated by rapidly heating and ionizing gas. This arc of plasma is then directed through a nozzle, allowing it to slice through metals such as steel, aluminum, and brass effortlessly. The CNC (computer numerical control) aspect of this technique enables the automation of cutting paths with significant accuracy, reducing the potential for human error and enhancing productivity. By exploring the basics of CNC plasma technology, newcomers can gain valuable insights into its practical uses, from artistic creations to industrial applications, thus setting the stage for deeper exploration into this exciting realm of metalworking.

What is CNC Plasma Cutting?

CNC plasma cutting is a sophisticated process widely used in metal fabrication for its precision, speed, and versatility. The technology operates by generating a high-temperature plasma arc that melts through conductive materials, effectively cutting them into desired shapes and dimensions. This technique can be utilized on various metals, including steel, aluminum, and copper, with thicknesses reaching up to several inches, depending on the power of the plasma cutter. According to industry reports, the global CNC plasma cutting market is projected to grow significantly, driven by the expanding manufacturing sector and the increasing demand for customized metal parts.

For beginners, understanding the essential components of a CNC plasma cutting system is crucial. These systems typically consist of a plasma torch, a power supply, a motion control unit, and a computer for programming the cuts. Novices should be aware that while CNC plasma cutting offers high efficiency and precision, safety precautions must be taken seriously to protect against the intense heat and emissions produced during the cutting process.

Tips: Always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and flame-resistant clothing, when operating a plasma cutter. Additionally, regularly inspect the equipment for signs of wear and tear, ensuring that all components function correctly to maintain optimal cutting performance.

Basic Components of a CNC Plasma Cutting System

A CNC plasma cutting system is composed of several key components that work together to achieve precise cutting. At the heart of the system is the CNC (Computer Numerical Control) unit, which serves as the brain of the operation. This unit interprets the design files and translates them into instructions that dictate the movement of the cutting torch. The accuracy of the CNC unit is essential for achieving the desired cut quality and precision.

Another crucial component is the plasma cutting torch. This torch generates a high-velocity jet of ionized gas, or plasma, capable of melting through metal materials. The torch is adjustable, allowing operators to control the height and speed of the cutting process. Additionally, the power supply is important as it provides the necessary electrical energy to create the plasma arc. A proper gas delivery system also ensures a consistent flow of gas, which is vital for maintaining the quality of the cut. Together, these components create a highly efficient system that streamlines metal fabrication processes, making it accessible for beginners in the field.

What is CNC Plasma Cutting and How Does it Work for Beginners - Basic Components of a CNC Plasma Cutting System

| Component | Description | Function |

|---|---|---|

| CNC Controller | The computer interface that sends instructions to the plasma cutter. | Coordinates the movement and operation of the cutting process. |

| Plasma Torch | The tool that creates a high-temperature plasma arc to cut through metal. | Heat metal to melting point and expel it to create a cut. |

| Power Supply | Provides the electrical energy required to create the plasma arc. | Generates the necessary voltage and current for the cutting process. |

| Cutting Table | The surface where the metal workpiece is placed during cutting. | Stabilizes the material and allows for accurate cuts. |

| Gas Supply | Delivers gases, usually compressed air, to assist in the cutting process. | Helps to cool the torch and enhances the cutting process. |

How CNC Plasma Cutting Works: A Step-by-Step Guide

CNC plasma cutting is a process that utilizes a high-velocity jet of ionized gas, known as plasma, to cut through electrically conductive materials. This technology is widely used in metal fabrication, allowing for precise and efficient cutting in various industries, including automotive and construction. The process begins with the CNC machine translating digital designs into movements, directing the cutting torch along the programmed path.

The step-by-step operation of CNC plasma cutting involves several key stages. Initially, the material is secured on the cutting table, ensuring stability during the operation. Next, the machine's software calibrates the cutting parameters, including speed and power settings, which are essential for achieving optimal quality. Once initiated, the torch ignites the plasma, melting the metal while a high-speed airflow blows the molten material away, creating a clean cut. According to industry reports, CNC plasma cutting can achieve accuracy levels of ±0.5mm, considerably enhancing productivity and reducing waste in material use.

Tips: When setting up your CNC plasma cutting operations, always check the quality of your consumables, including nozzles and electrode designs, as these can significantly impact the cut quality and longevity of your equipment. Additionally, maintaining a clean work environment and regularly inspecting machine parts can help prevent downtime caused by unexpected maintenance issues.

Safety Precautions When Using CNC Plasma Cutters

When operating CNC plasma cutters, adhering to safety precautions is of utmost importance to ensure the safety of the operator and the integrity of the workspace. According to the American Welding Society, over 2,000 injuries related to metalworking occur annually, highlighting the risks involved. Proper personal protective equipment (PPE) such as flame-resistant clothing, safety glasses, and gloves must be worn to mitigate hazards associated with sparks, heat, and sharp metal fragments.

Additionally, it is critical for operators to utilize proper ventilation in the workspace to avoid inhaling harmful fumes generated during the cutting process, as these can lead to respiratory issues over time.

Another essential aspect of safety in CNC plasma cutting is maintaining a clean and organized work environment. The National Safety Council reports that slips, trips, and falls are among the leading causes of injuries in manufacturing sectors. Keeping the area free of clutter, ensuring that all materials are secured, and regularly inspecting equipment for any wear or malfunction can significantly reduce the likelihood of accidents. Operators should also undergo thorough training to understand the machine's capabilities and limitations, and follow the manufacturer's guidelines strictly.

By fostering a culture of safety and awareness, facilities can significantly decrease the risk of incidents and promote a more efficient operational environment.

Applications of CNC Plasma Cutting in Various Industries

CNC plasma cutting is an advanced technique widely employed across various industries, ranging from automotive to aerospace. This technology utilizes a high-velocity jet of ionized gas, or plasma, to cut through electrically conductive materials like steel, aluminum, and copper with precision and speed. According to a recent report by MarketsandMarkets, the global CNC plasma cutting market is expected to grow significantly, reaching a valuation of over $1.5 billion by 2026, demonstrating its increasing importance in manufacturing processes.

In the automotive industry, CNC plasma cutting is used to fabricate components such as chassis parts and brackets. Its ability to make intricate cuts with minimal material wastage contributes significantly to production efficiency. Similarly, in the construction sector, this technology plays a crucial role in creating structural steel elements and custom frames, allowing for rapid prototyping and adjustments. As reported by IBISWorld, the metal fabrication industry, where CNC plasma cutting is a core process, is projected to grow by 5% annually, highlighting the rising demand for such efficient cutting methods.

Tips: When considering CNC plasma cutting for projects, ensure the material thickness and type align with the machine's capabilities to guarantee optimal performance. Additionally, maintaining the plasma cutter and regularly checking consumables can lead to better output quality and longer equipment lifespan. Understanding the specific applications in your industry can further enhance the benefits of integrating CNC plasma cutting into your operations.

Related Posts

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success

-

7 Key Advantages of Choosing the Best Plasma Cutting Machine for Your Business

-

2025 How to Choose the Best Small CNC Plasma Cutter for Your Needs

-

What Is an Industrial Plasma Table and How Does It Revolutionize Metal Fabrication?

-

What is the Future of the Best Small CNC Plasma Tables in Global Manufacturing?

-

Understanding the Specifications of the Best Industrial CNC Plasma Table and How to Use It