The Ultimate Guide to CNC Plasma Cutting in 2025 for Beginners

As we step into 2025, the landscape of CNC plasma cutting continues to evolve, making it an exciting time for both seasoned professionals and newcomers alike. According to industry expert John Smith, "CNC plasma cutting is not just about the technology; it's about harnessing creativity to bring designs to life with precision." This statement underscores the significance of mastering CNC plasma techniques, especially for beginners eager to explore this innovative field.

In this ultimate guide, we will delve into the essential aspects of CNC plasma cutting, from understanding the basic concepts to grasping the intricacies of effective machine operation. The advancements in technology over the years have transformed CNC plasma into an accessible tool for artists, fabricators, and manufacturers, enabling them to create intricate designs with speed and efficiency.

Whether you're considering diving into CNC plasma cutting for hobbyistic endeavors or professional aspirations, this guide aims to equip you with the knowledge and skills necessary to succeed. Join us as we unlock the potential of CNC plasma and embark on a journey toward mastering this powerful cutting technique.

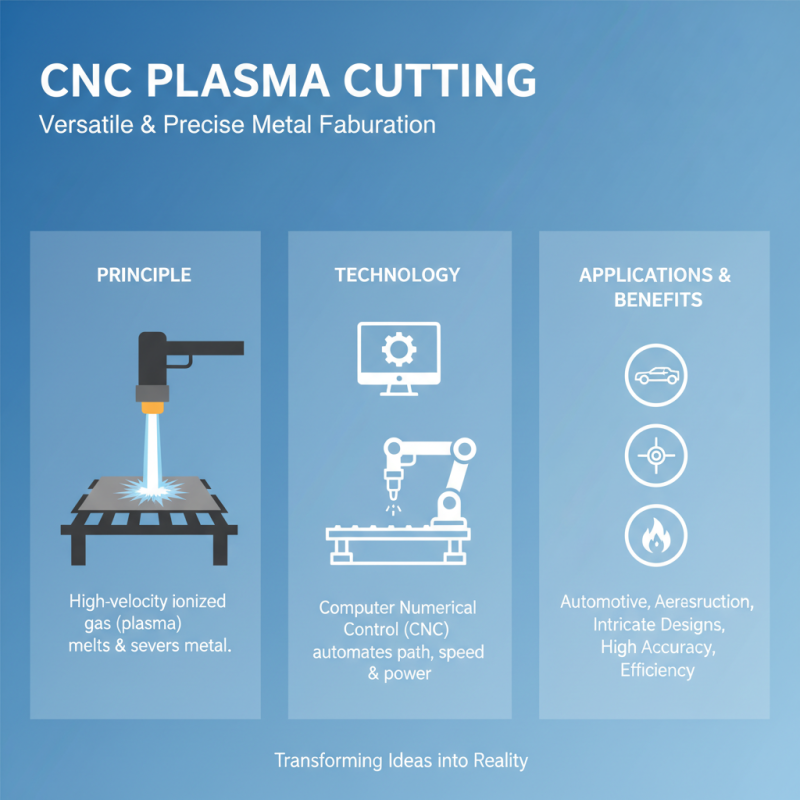

Understanding CNC Plasma Cutting: Principles and Applications

CNC plasma cutting is a versatile and efficient method used in various industries for shaping and cutting metal materials. The principle behind this technology is the use of a high-velocity jet of ionized gas, or plasma, to melt and sever metal. At its core, the CNC (Computer Numerical Control) system automates the cutting process, allowing for precise control over the speed, path, and power of the plasma arc. This automation transforms complex design ideas into reality, making it an ideal choice for fabricating intricate components with high accuracy.

In addition to its precision, CNC plasma cutting finds its applications in diverse fields ranging from automotive to aerospace and art. Industries utilize this technology to create custom parts, perform repairs, or even produce large scale art installations. The ability to cut through various thicknesses of metals, including steel and aluminum, enhances its utility across many sectors. As the technology evolves, new advancements are continuously expanding its potential, paving the way for innovative applications that can address the growing demands of modern manufacturing.

Essential Equipment for CNC Plasma Cutting: A Beginner's Toolbox

When diving into the world of CNC plasma cutting, having the right tools is essential for success, especially for beginners. A well-equipped toolbox lays the foundation for effective and efficient cutting projects. At the core of your equipment should be a reliable CNC plasma cutter, which operates by using a high-velocity jet of ionized gas to melt and expel material from the workpiece. This machine not only ensures precision but also boosts productivity, making it indispensable for those new to the craft.

Alongside the plasma cutter, several other tools and accessories are crucial. A computer with CAD/CAM software will allow you to create precise designs and control the cutting process, enhancing your overall capabilities. Protective gear, including goggles and gloves, is equally important to ensure safety while operating the machinery. Additionally, spend time gathering a proper work surface and clamps; these will help stabilize your materials, allowing for clean and accurate cuts. A good understanding of the setup and maintenance of this equipment will aid beginners in mastering the art of CNC plasma cutting effectively.

The Ultimate Guide to CNC Plasma Cutting in 2025 - Essential Equipment Overview

Setting Up Your CNC Plasma Cutting Machine: Step-by-Step Guide

Setting up your CNC plasma cutting machine requires careful planning and precision. Start by selecting a suitable workspace that is well-ventilated and equipped with adequate electrical supply to support your machine's power requirements. Once you have your space ready, begin by assembling your machine according to the manufacturer’s instructions. Pay attention to the assembly of the gantry and axis systems to ensure smooth operation.

Tips: Ensure that you have all your tools on hand before starting the assembly process. This includes wrenches, screwdrivers, and a level to align the machine properly. Double-check all connections and fittings to prevent issues later on.

Next, connect your CNC plasma cutter to your computer for software installation. The CNC software will be essential in translating your designs into precise cutting paths. Take the time to familiarize yourself with the software interface, as it will significantly streamline your workflow. Additionally, calibrate your cutting parameters, including speed and torch height, to achieve optimal performance and quality in your cuts.

Tips: Regularly update your software to benefit from enhancements and features that can improve functionality. Always refer to safety manuals and guidelines to ensure you are adhering to best practices while operating your CNC plasma cutting machine.

Safety Considerations and Best Practices for New CNC Plasma Users

When venturing into the world of CNC plasma cutting, safety should be your top priority. This cutting-edge technology can be incredibly powerful, but it also poses various risks if not handled properly. Always don personal protective equipment (PPE) including gloves, safety goggles, and flame-resistant clothing. Ensure your workspace is well-ventilated to avoid inhaling harmful fumes, and keep a fire extinguisher nearby, as plasma cutting generates intense heat and sparks that can ignite flammable materials.

Tips: Before starting any project, take the time to familiarize yourself with the CNC plasma cutter’s manual. Understanding the machine's functions and emergency shut-off procedures can significantly reduce the risk of accidents. Additionally, regularly inspect cables and connections for wear and tear; damaged equipment can lead to hazardous situations.

Best practices also include maintaining a clean workspace. Remove any clutter and unnecessary items from your cutting area to minimize distractions and potential hazards. Develop a routine for checking the integrity of your work setup, ensuring that everything is secure and in place before you begin cutting. This diligent approach will help you cultivate safety awareness as a new CNC plasma user, allowing for a more productive and secure cutting experience.

Troubleshooting Common Issues in CNC Plasma Cutting for Beginners

When mastering CNC plasma cutting, beginners often encounter a variety of common issues that can hinder their progress and affect the quality of their work. One of the most frequent problems is poor cutting quality, which can manifest as rough edges or incomplete cuts. This issue often arises from incorrect settings in the CNC software, such as inadequate cutting speed or the wrong amperage being used. To troubleshoot these problems, ensure your machine is calibrated correctly, and experiment with different settings to find the optimal balance for the materials being used. Cleaning the workpiece and ensuring stable clamping can also improve the overall outcome.

Another prevalent issue is the occurrence of inconsistent arc length, which may lead to disruptions in cutting quality. This inconsistency can result from a misaligned torch or an unstable power supply. Beginners can address this by regularly checking the alignment of the torch, securing any loose connections, and inspecting power sources for fluctuations. Furthermore, ensuring that the consumables, such as electrodes and nozzles, are in good condition will help maintain a stable cutting arc and enhance performance. Regular maintenance and thorough inspections can significantly reduce downtime and improve productivity in CNC plasma cutting.

The Ultimate Guide to CNC Plasma Cutting in 2025 for Beginners

| Common Issues | Symptoms | Possible Causes | Troubleshooting Steps | Prevention Tips |

|---|---|---|---|---|

| Poor Cut Quality | Rough edges, Excessive dross | Incorrect speed, Worn consumables, Improper gas flow | Adjust cut speed, Replace consumables, Check gas pressure | Regular maintenance, Keep a log of consumable life |

| Inconsistent Cuts | Variability in thickness, Uneven bevel | Setup errors, Material warping | Realign the material, Check grounding | Stable work environment, Proper material handling |

| Arc Stability Issues | Flickering arc, Frequent shutdowns | Improper electrical connections, Low gas flow | Check connections, Adjust gas settings | Routine checks, Quality gas supply |

| No Cutting Action | Machine powers on but no cut | Worn out torch, Software errors | Inspect torch assembly, Restart software | Regular software updates, Monitor torch condition |

| Overheating | Unit shuts down, Extended stopping time | Insufficient cooling, High duty cycle | Clear vents, Reduce workload | Ensure adequate ventilation, Monitor duty cycle |

Related Posts

-

What is CNC Plasma Cutting and How Does it Work for Beginners

-

What is the Future of the Best Small CNC Plasma Tables in Global Manufacturing?

-

2025 How to Choose the Best Small CNC Plasma Cutter for Your Needs

-

What Is an Industrial Plasma Table and How Does It Revolutionize Metal Fabrication?

-

Understanding the Specifications of the Best Industrial CNC Plasma Table and How to Use It

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success