How to Choose the Right Plasma Cutting Table for Your Needs?

Choosing the right plasma cutting table can be a challenging task for many fabricators. Expert Mike Johnson notes, "The right cutting table can elevate your work efficiency." With various options available, understanding your specific needs is crucial. It's not just about price; features matter too.

A plasma cutting table can be a significant investment. You need a tool that aligns with your project requirements and your workspace. Lights, table size, and material types all play a role in your decision. Many overlook these details, leading to frustration later.

Consider how often you will use the table and the complexity of your work. A larger table may seem appealing but might not fit in your shop. Additionally, some tables are easier to maintain than others. Reflecting on these aspects will help guide your choice for the best plasma cutting table for you.

Choosing the Right Plasma Cutting Table: Factors to Consider

Choosing the right plasma cutting table can significantly impact your workflow. Several factors must be considered. The size of the table is crucial. Assess the materials you will be cutting and ensure the table can accommodate them. A larger table allows for more significant projects but may consume more space.

The thickness of the materials is another vital aspect. Different tables handle specific material thicknesses. If you plan to cut thick steel, ensure your table is appropriate. Some tables are better for light materials, while others excel with heavy ones. Don't overlook the quality of the cutting surface. A sturdy, flat surface aids in precise cuts.

Budget considerations also play a role. Higher quality tables may cost more, but they often provide better performance. Balance your needs with your budget, and be aware of what you can compromise on. Remember, the perfect table doesn't exist. Everyone has different needs, and reflecting on your requirements is essential. Avoid rushing this decision; the right choice may take time to identify.

Types of Plasma Cutting Tables: An Overview of Options Available

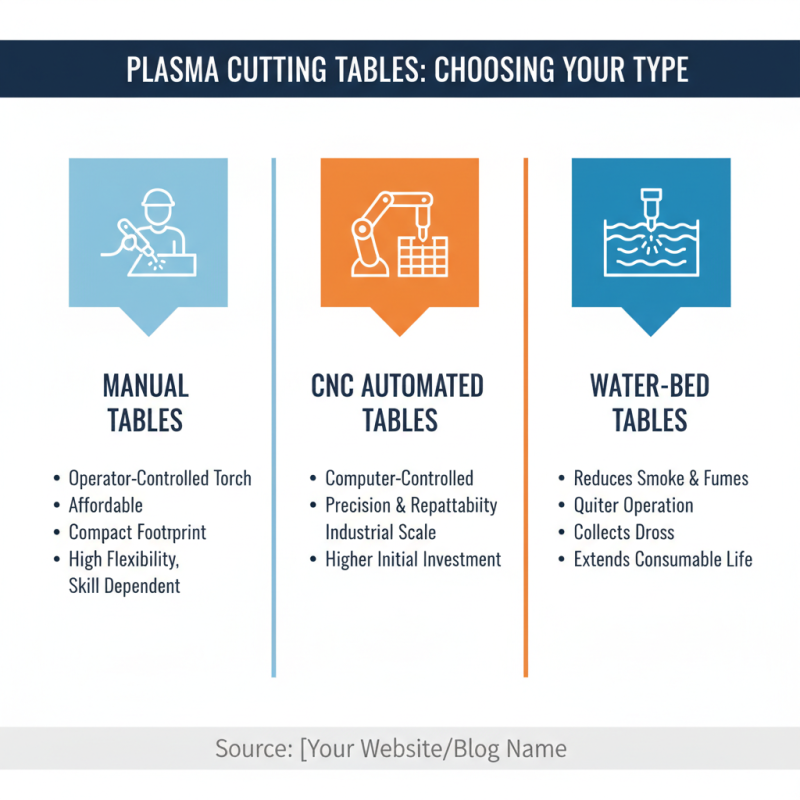

When selecting a plasma cutting table, understanding the types available is crucial. There are various options suited to different needs. A basic manual table offers flexibility but requires more skill. These tables are often more affordable and can work in smaller spaces.

In contrast, automated plasma cutting tables increase efficiency. They come in various sizes and are perfect for larger projects. These setups use computerized systems, reducing human error. However, they can be expensive and may require training to operate effectively.

Another popular option includes water table setups. These tables can minimize fumes and noise during the cutting process. They are often favored for intricate designs. Despite their advantages, they may require more maintenance. Each type presents unique benefits and challenges, making it essential to consider your specific needs.

Key Features to Assess When Evaluating Plasma Cutting Tables

Choosing the right plasma cutting table is crucial for optimal performance. Several key features can significantly impact your workflow and outcomes. The table's size is vital. A larger table accommodates bigger materials. Industry reports indicate that a workstation should have at least 4x8 feet of workspace for standard projects.

Accuracy is another important feature. Tables with advanced motion control systems provide precise cuts. According to recent studies, a 1% increase in accuracy can lead to a 5% reduction in material waste. This is significant in today’s competitive market. Additionally, speed is essential. A cutting table with higher speeds can enhance productivity, but it may compromise quality if not managed properly.

Consider the software compatibility as well. Advanced software integrates with CAD systems, streamlining the workflow. Inadequate software could lead to inefficiencies. Many users report frustration with complicated setups or lack of updates. Lastly, think about your long-term needs. A table that fits now may not suffice later. It’s essential to reflect on both current projects and future expansions. Balancing these features can be challenging, but it's necessary for achieving reliable cutting results.

Understanding Your Project Requirements for Optimal Table Selection

When choosing a plasma cutting table, understanding your project requirements is essential. The size of your workspace will impact your selection. If you often cut large sheets of metal, a bigger table would be beneficial. However, a compact setup might suit smaller projects. Watch for any space limitations in your workshop. A table too big could hinder your workflow.

Material thickness is another critical factor. Different tables can handle varying material thicknesses. If your projects often involve thick materials, ensure your table can accommodate them. Look into the types of metals you'll work with as well. Some tables are not as efficient with certain materials. Consider your cutting frequency too; a table for occasional use may differ from one for daily heavy-duty work. Think about weight and transportability. A heavy table can be stable but hard to move.

It’s important to reflect on your long-term needs. Choosing a table that suits your current project might not be wise for the future. Ask yourself if flexibility matters. A table that adapts to different projects could save you frustration down the line. Explore additional features like automation and software compatibility. These might enhance your productivity, but they also add complexity. Balancing simplicity and capability is key to making the right choice.

Budget Considerations: Finding a Plasma Cutting Table That Fits Your Needs

When considering a plasma cutting table, budget is a crucial factor. It's easy to get overwhelmed by features. You need to ask yourself what you really need. Some tables are suitable for light work, while others are designed for heavy-duty tasks. A higher price tag often comes with better capabilities, but do you need all those features?

Evaluate how much you plan to use the table. If it's occasional work, a cheaper model might suffice. On the flip side, investing in a more expensive table makes sense for regular use. Also, remember that maintenance costs add up. A low upfront cost can mean higher repairs down the line.

Consider additional expenses, like consumables. Some tables require specific parts that can increase ongoing costs. Cheap options might save you initially, but they can lead to frustration later. Carefully weigh your priorities. Sometimes, it's worth spending a little more to avoid headaches in the future.

Related Posts

-

The Future of Metal Fabrication with Advanced Plasma Cutting Tables

-

7 Best HD Plasma Cutters for Precision Metal Cutting in 2023

-

Maximizing Efficiency: How a Plasma Cutting Table Transforms Metal Fabrication Workflows

-

Maximizing ROI on Best Industrial CNC Plasma Tables: How Superior After-Sales Service and Low Maintenance Costs Drive Success

-

Precision Engineering in China: Elevating Global Manufacturing with the Best Plasma Cutting Technology

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers