How to Choose the Right Small Plasma Table for Your Business Needs

In today's competitive manufacturing landscape, selecting the right small plasma table is crucial for optimizing efficiency and enhancing productivity. According to a recent report by MarketsandMarkets, the global plasma cutting machine market is projected to reach USD 5.24 billion by 2025, driven by the growing demand for precise and efficient cutting technologies across various industries, including automotive and aerospace. The versatility of small plasma tables allows businesses to perform intricate cuts on a variety of materials, improving workflow and reducing material waste. As small manufacturers and startups increasingly adopt these advanced machines, understanding the key factors—such as power requirements, table size, and cutting capabilities—becomes essential for ensuring that your investment aligns with your operational needs. This guide will help you navigate the complexities of choosing a small plasma table that not only meets your business requirements but also positions you for long-term success.

Identifying Your Business Requirements for a Plasma Table

When selecting the right small plasma table for your business, it is crucial to start by identifying your specific business requirements. Consider factors such as material types, thicknesses, and the complexity of designs you'll be working with. According to the Fabricators & Manufacturers Association, businesses that specialize in metal fabrication often require plasma cutting tables capable of handling a variety of materials, including steel, aluminum, and brass, to accommodate diverse project demands.

Additionally, the cutting speed and precision are vital. A report from the American Welding Society indicates that plasma tables that offer advanced features like automated height sensing and integrated software can significantly enhance productivity, leading to a 30% increase in cutting efficiency. Understanding your operational needs, including space constraints and budget, can further refine your options. By aligning your purchase with both technical specifications and operational workflows, you can ensure that the plasma table you choose will enhance your capabilities and contribute to your overall business success.

Understanding the Different Types of Small Plasma Tables

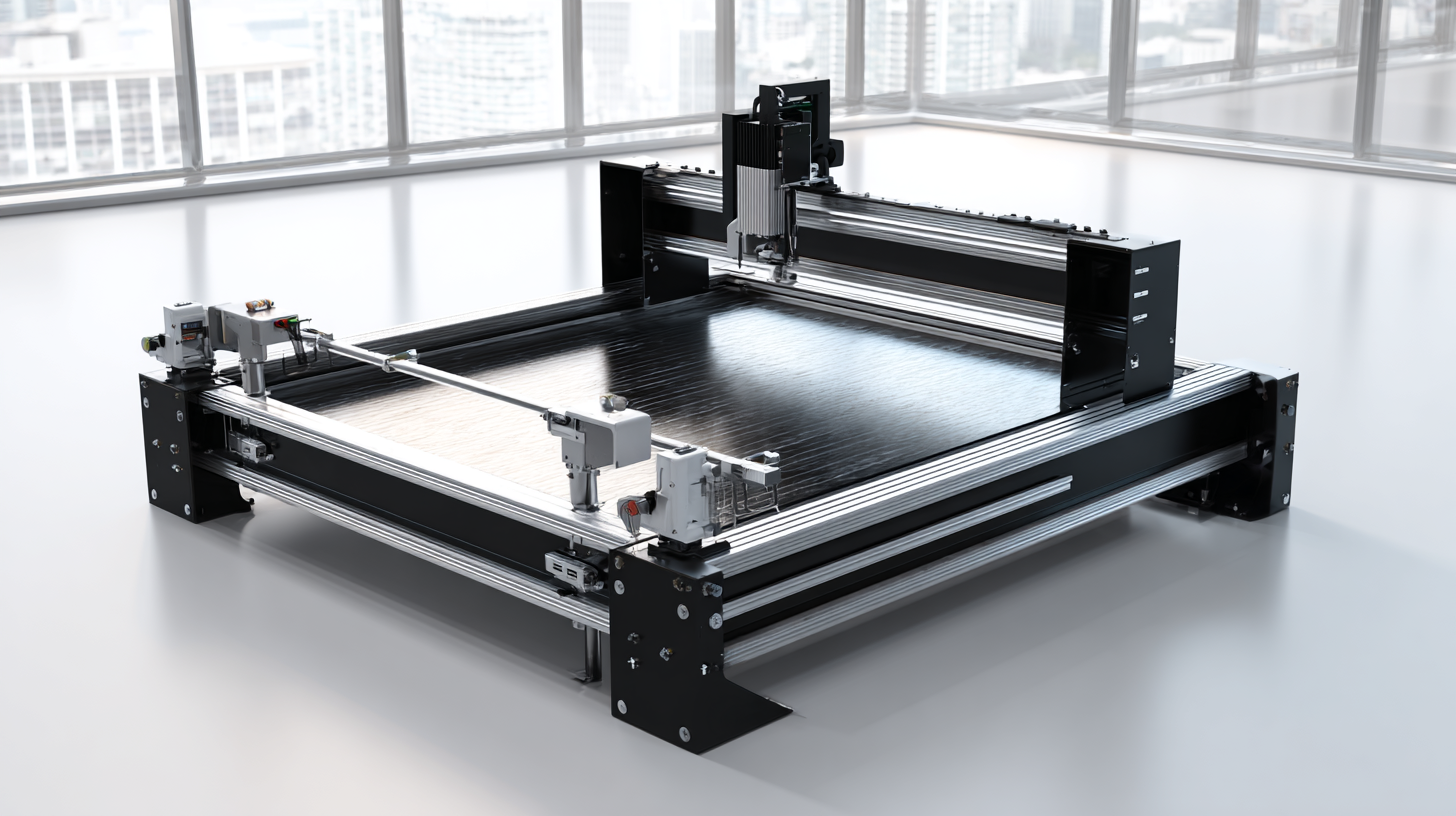

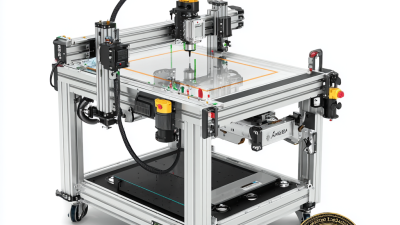

When selecting a small plasma table, it’s essential to understand the different types available to suit your specific business needs. Small plasma tables generally fall into three categories: entry-level models, mid-range machines, and high-end professional systems. Entry-level models are ideal for hobbyists or small businesses with limited budgets, offering basic features that allow for straightforward cutting tasks. These machines often come with a smaller cutting area but are perfect for projects that don’t require extensive operation.

Mid-range plasma tables provide a balance between affordability and advanced features. They are designed for growing businesses that need increased cutting capacity and better precision. These machines typically offer more powerful plasma sources and larger workspaces, accommodating a variety of materials and thicknesses. Additionally, mid-range options often include advanced software for enhanced control and efficiency, making them suitable for more complex tasks.

High-end professional systems are tailored for businesses that demand top-tier performance and versatility. They usually incorporate state-of-the-art technology, such as fully automated processes, higher cutting speeds, and superior cut quality. This category of plasma tables is designed for heavy-duty use, enabling businesses to handle large-scale projects or intricate designs with ease. Understanding these distinctions can help you identify which small plasma table best aligns with your operational needs and budget constraints.

How to Choose the Right Small Plasma Table for Your Business Needs

| Table Type | Cutting Area (mm) | Max Material Thickness (mm) | Power Consumption (kW) | Weight (kg) |

|---|---|---|---|---|

| Entry-Level Table | 1000 x 1000 | 8 | 1.5 | 200 |

| Mid-Range Table | 1500 x 1500 | 12 | 2.5 | 400 |

| Advanced Table | 2000 x 3000 | 20 | 3.5 | 800 |

Evaluating Key Features: Size, Speed, and Precision

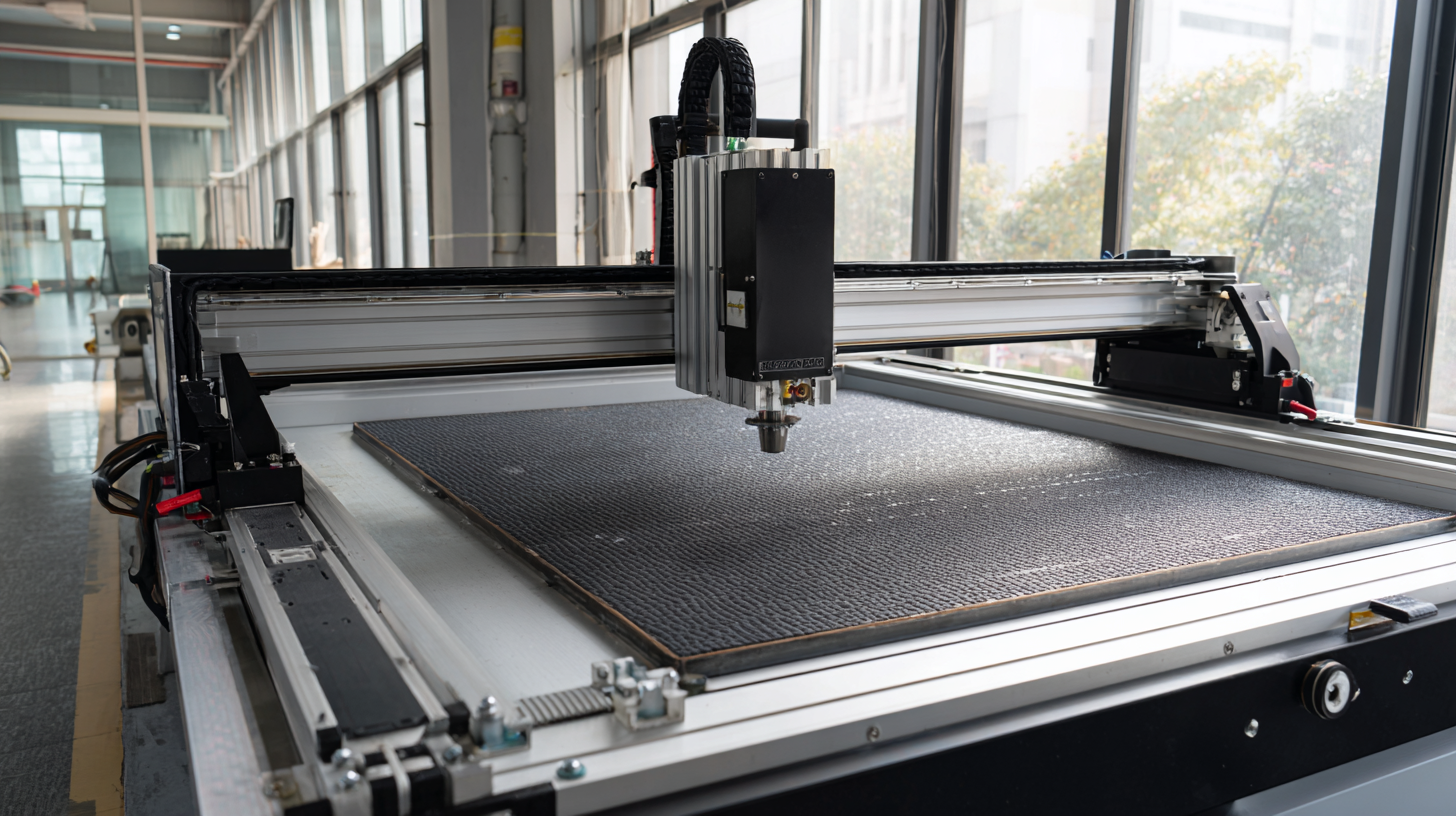

When selecting a small plasma table, evaluating key features is crucial to meeting your business needs effectively. First, size plays a pivotal role in determining the table's suitability for your workspace and the type of projects you undertake. Industry reports indicate that businesses utilizing tables with work areas between 4x4 to 5x10 feet have found this range to balance capability with spatial efficiency, enabling them to handle a variety of materials without overwhelming their production floor. Assessing your average workpiece dimensions can guide you in narrowing down your options.

Speed and precision are similarly critical factors that can significantly influence your operational efficiency. According to a recent study by the Fabricators & Manufacturers Association, plasma cutting systems with higher cutting speeds—averaging around 800 ipm (inches per minute)—can increase productivity by up to 25%. Additionally, precision is paramount in sectors like automotive and aerospace, where tolerances may be as tight as ±0.005 inches. Investing in a plasma table that offers advanced motion control technology and high-resolution plasma systems ensures quality results, ultimately enhancing your competitive edge in the market.

Budgeting for Your Plasma Table Investment

When investing in a small plasma table for your business, budgeting is crucial. It’s essential to assess not just the initial purchase price but also operational costs, including maintenance, software, and supplies. A well-planned budget should account for these ongoing expenses, as they can significantly impact your overall investment over time. Companies often overlook total cost of ownership, which includes electricity consumption and the potential need for additional workforce training.

Additionally, consider the return on investment (ROI) of the plasma table. Investing in a machine that meets your specific needs can lead to increased efficiency and productivity in your operations. In light of trends seen in various industries, including pharmaceuticals, where research and development require precise cutting and crafting, a high-quality plasma table can be a strategic asset.

Aligning your budget with the potential benefits and savings from improved production capabilities is essential to making an informed choice.

Comparing Brands and Models: What to Look For

When selecting the right small plasma table for your business, it's essential to compare various brands and models based on key performance indicators. According to a recent industry report from IBISWorld, the demand for plasma cutting machines has risen by 5.3% annually, indicating a growing market that emphasizes quality and efficiency. Factors such as cutting speed, ease of use, and software compatibility should be considered. For instance, models by Hypertherm are often noted for their superior arc technology, which can enhance precision, while CNC machines from PlasmaCAM are favored for their user-friendly interface.

Tips: Always look for brands that offer robust customer support and warranty options, as this can significantly reduce downtime. Additionally, consider the availability of consumable parts; a model with readily accessible supplies can lead to cost savings in the long run.

Another critical aspect is the table's size and weight capacity. Larger tables can accommodate bigger projects but may require more floor space and power consumption. According to TechSci Research, smaller businesses often prefer compact models that offer versatility without compromising functionality. Verifying whether the table can handle your anticipated workload is crucial for efficient operations.

Tips: Take advantage of demo sessions or live tests, if available, to assess the table's functionality before purchase. Also, factor in future scaling needs; a model that can adapt to growing business demands will save you from potential costly replacements.

Related Posts

-

How to Navigate Import and Export Certifications for Best Small Plasma Tables

-

7 Compelling Reasons Why the Best Plasma Table Will Transform Your Production Line

-

7 Reasons Why the Best Industrial Plasma Table is an Essential Investment for Global Buyers

-

What Is an Industrial Plasma Table and How Does It Revolutionize Metal Fabrication?

-

Ultimate Guide to Choosing the Best Industrial Cutting Table for Your Manufacturing Needs

-

Exploring Innovative Alternatives to the Best Cutting Table for Your Workshop