What Are the Benefits of Using a Laser Cutting Machine?

In the rapidly evolving landscape of manufacturing, the laser cutting machine has become a cornerstone technology. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $5.3 billion by 2025. This growth highlights the increasing demand for precision and efficiency in various industries.

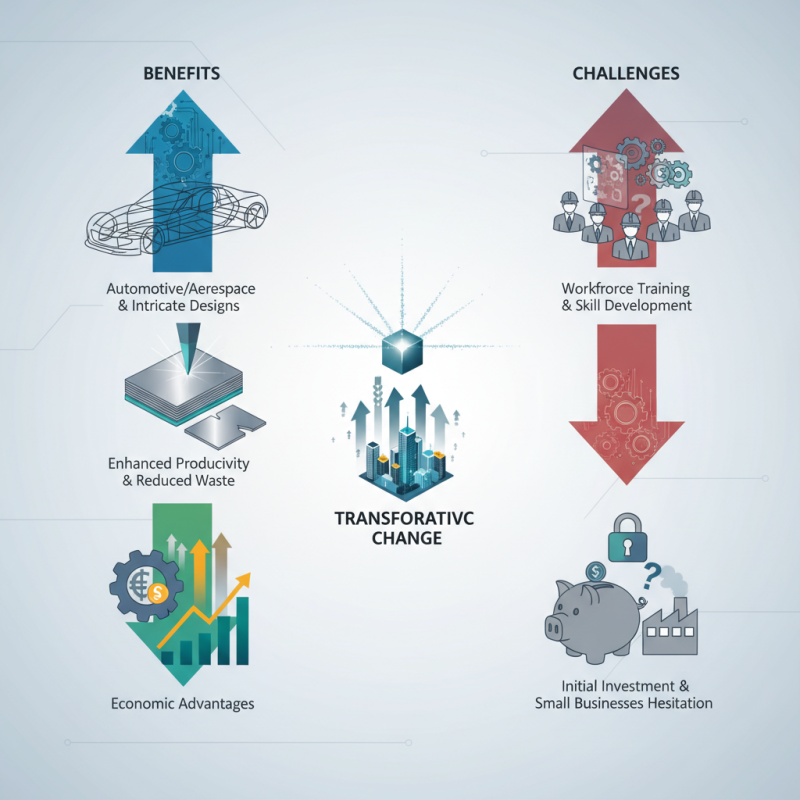

Industry expert Dr. Emily Chen states, "The adaptability of laser cutting machines allows for innovations that exceed traditional cutting methods." This adaptability is evident across sectors such as automotive, aerospace, and metal fabrication, where intricate designs and complex shapes are required. Users often report enhanced productivity and reduced waste, underscoring the machine's economic advantages.

However, the implementation of laser cutting technology is not without challenges. Companies must train their workforce to handle these advanced machines. Additionally, the initial investment can be significant, leading many small businesses to hesitate. Despite these hurdles, the benefits of using a laser cutting machine can be transformative for those who embrace the change.

Understanding Laser Cutting Technology and Its Mechanism

Laser cutting technology has revolutionized the manufacturing world. It uses focused laser beams to cut through materials with precision. This process employs a high-intensity beam that melts or vaporizes the material. It allows for intricate designs that traditional methods struggle to achieve. The mechanism offers flexibility in cutting various materials like metal, wood, and plastic.

Precision is one of the key benefits. The laser beam moves with exceptional accuracy, ensuring clean edges. However, occasional misalignments can occur, frustrating designers. This technology also reduces waste, as it uses a narrow beam that minimizes leftover material. There’s less need for further processing. Yet, understanding the complexities is vital. In some cases, the initial setup might take longer due to required calibrations, which can lead to time loss.

Despite its advantages, there are limitations. For instance, thicker materials may require multiple passes, impacting efficiency. Operators must also consider the heat-affected zone. Managing these factors is crucial for achieving desired results. Exploring these nuances can enhance understanding and skills in using laser cutting machines effectively.

Key Advantages of Laser Cutting Machines in Manufacturing

Laser cutting machines provide remarkable advantages in manufacturing. They offer precision that is hard to achieve with traditional cutting methods. The process involves directing a high-powered laser beam onto the material. This results in clean, sharp edges without the need for further finishing. Industries ranging from aerospace to fashion benefit from this technology. The versatility of materials, including metals and plastics, is another key advantage.

Quick turnaround times set laser cutting apart from conventional techniques. The machines can operate continuously, minimizing downtime. Moreover, their ability to handle complex designs fosters innovation. However, some users encounter a learning curve with software and programming. Skilled operators are essential for optimal results. Investing in training can bridge this gap, leading to better output.

Cost savings also play a significant role. While initial investments may be high, the efficiency gained pays off over time. Reduced waste and energy consumption contribute to lower operational costs. Yet, it is vital to continuously evaluate the machine’s capabilities. Regular maintenance ensures long-term functionality. Effectively integrating laser cutting can transform manufacturing processes.

Applications of Laser Cutting Across Various Industries

Laser cutting has transformed various industries by enhancing precision and efficiency. In manufacturing, it serves many roles. For instance, sheet metal cutting and engraving have benefited from laser technology. Complex designs can be achieved with minimal waste. The machine creates clean edges, reducing the need for further processing.

In the textile industry, laser cutting is employed for intricate patterns and designs. Fashion designers use it to achieve unique fabric cuts. This can save time and reduce labor costs. Jewelry making also sees advantages from laser cutting. Fine details in metal and stone can be crafted easily, creating high-quality pieces.

However, there are challenges. Not all materials are suitable for laser cutting. Some may produce harmful fumes. Additionally, there can be a steep learning curve for operators. Understanding the equipment ensures better results. While the advantages are clear, careful consideration is essential. Users must reflect on the specific needs of their projects.

Comparative Analysis: Laser Cutting vs. Traditional Cutting Methods

When comparing laser cutting to traditional cutting methods, several factors come into play. Laser cutting relies on focused beams of light to slice through materials. This process often results in cleaner edges and more precise cuts. In contrast, traditional methods like saws or knives may leave rough edges or require additional finishing work.

Laser cutting machines can handle complex designs that would be challenging for manual tools. They create intricate patterns with minimal human intervention. However, setting up a laser cutter may require more initial investment and training. Traditional methods are usually more accessible, making them suitable for smaller operations or hobbyists. Yet, they demand more time and labor to achieve similar precision.

Moreover, the versatility of laser machines is noteworthy. They can work on various materials, including metals, plastics, and fabrics. But sometimes, they struggle with thicker materials. Users might encounter difficulties when trying to cut through dense substances. Overall, both methods have their merits, and the best choice depends on the specific requirements of the project.

Economic and Environmental Benefits of Utilizing Laser Cutting Solutions

Laser cutting machines are becoming increasingly popular across various industries. Their economic benefits are evident. According to a recent industry report, laser cutting can reduce manufacturing costs by up to 30%. This reduction comes from decreased material wastage and shorter processing times. Businesses can produce more products in less time. Efficiency matters, and laser cutting helps achieve that.

Environmental benefits are significant as well. Traditional cutting methods often lead to more scrap material. In contrast, laser cutting utilizes a high-precision process that minimizes waste. A study found that companies using laser technology reduced their waste by over 50%. This is crucial for organizations aiming for sustainability. Furthermore, laser machines consume less energy compared to conventional methods, which means lower operational costs and a reduced carbon footprint.

However, the initial investment in laser cutting technology can be high. Smaller businesses may struggle to afford it. They might miss out on the long-term savings and environmental advantages. Adopting this technology requires careful consideration. Balancing the costs with the potential benefits is essential. As laser cutting continues to evolve, its role in the industry promises to grow, presenting both challenges and opportunities.