2025 Global Purchasing Guide to Best CNC Table Advancements and Trends

As industries continue to evolve in a rapidly changing global market, the demand for precision in manufacturing processes has never been higher. The CNC table, an essential component in automated machining, stands at the forefront of these advancements. According to a recent report from MarketsandMarkets, the CNC machine market is expected to reach $117 billion by 2025, driven by the surge in automation across sectors. This growth is directly linked to the increasing need for efficiency and accuracy in production lines, as well as the reduction of operational costs. Furthermore, recent trends show a significant shift toward smart technologies and IoT integration within CNC systems, which enhance both functionality and user experience. In this blog, we will explore the latest advancements and trends in CNC tables, including the significance of import-export certifications that ensure compliance and quality in this vital industry.

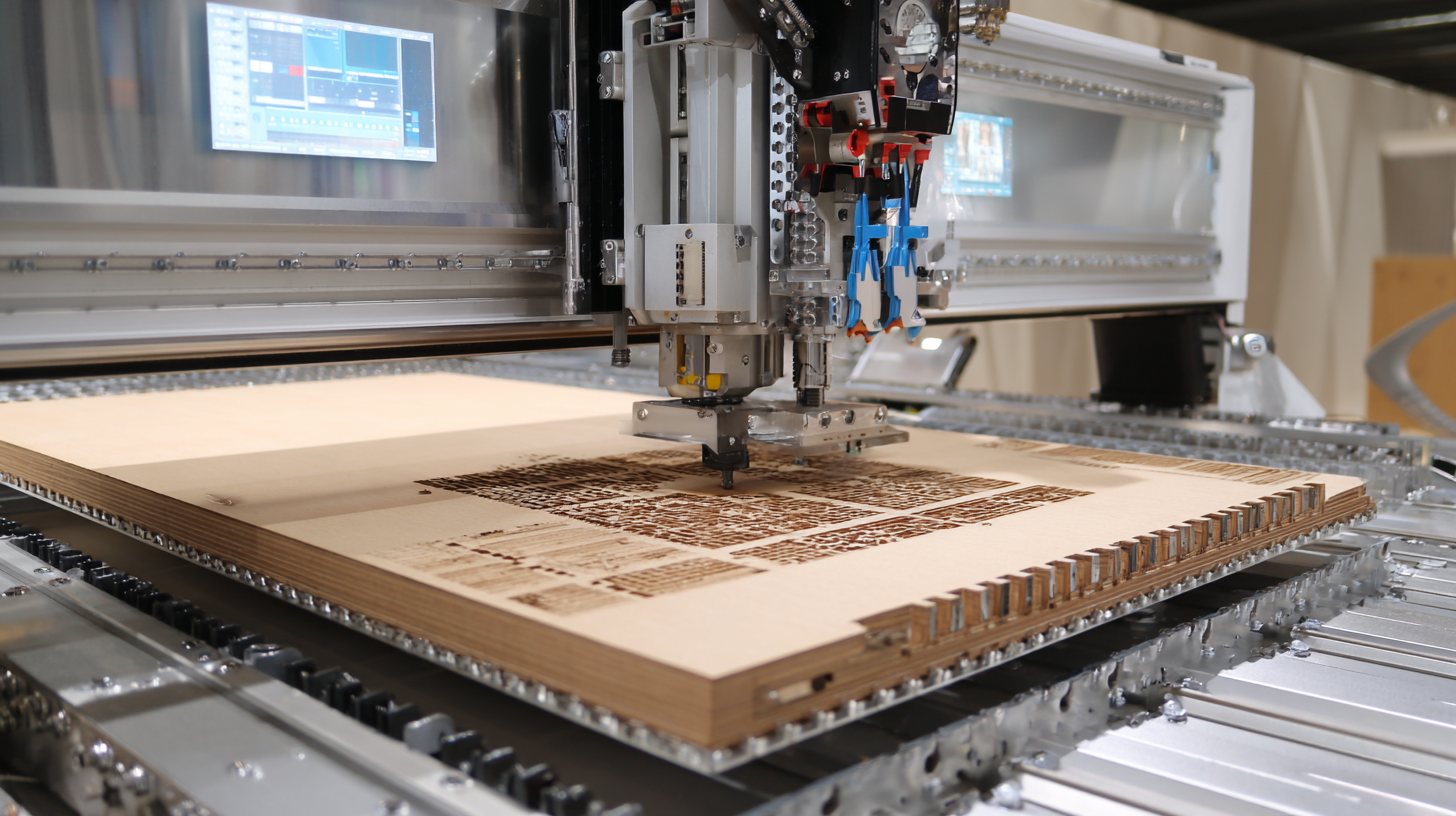

The Latest Innovations in CNC Table Technology for 2025

As we approach 2025, the landscape of CNC table technology is evolving at a rapid pace. Innovations are aimed at enhancing precision, efficiency, and operator safety, making it crucial for businesses to stay informed. Leading manufacturers are now integrating AI-driven features that optimize cutting paths and reduce material waste. Additionally, advancements in materials are resulting in CNC tables that are lighter yet more durable, facilitating easier transport and setup without compromising performance.

Tips for selecting the best CNC table include assessing your workspace and choosing a model that aligns with your production needs. Consider features such as modular designs that allow for future upgrades, ensuring the longevity of your investment. Furthermore, pay attention to customer reviews and testimonials; real-world experiences can provide valuable insights into the reliability and usability of specific models.

Moreover, connectivity is becoming an essential aspect of modern CNC tables. Look for options that support IoT capabilities, enabling remote monitoring and maintenance. This not only streamlines workflow but also reduces downtime through more proactive management of equipment. Stay informed on emerging trends to make an educated choice that aligns with your operational goals in the coming years.

Key Trends Shaping the Future of CNC Machining Tables

The landscape of CNC machining tables is being transformed by the integration of advanced automation and artificial intelligence. In 2025, manufacturers are expected to increasingly adopt IoT-enabled equipment that not only enhances productivity but also enables real-time data processing. According to a recent industry report, the CNC automation market is projected to grow at a compound annual growth rate (CAGR) of 10.47% from 2022 to 2026, indicating a significant shift towards smart manufacturing solutions.

Key trends shaping the future of CNC machining tables include the rising demand for robotic automation, which streamlines processes such as tool changes and material handling. This shift not only reduces operational costs but also mitigates human error, leading to more precise outcomes. Additionally, AI is playing a critical role by optimizing production schedules and predictive maintenance, which helps industries anticipate downtimes and enhance machine utilization. With manufacturers embracing these cutting-edge technologies, the capability of CNC machining tables is set to redefine operational efficiency in various sectors.

2025 Global Purchasing Guide to CNC Table Advancements

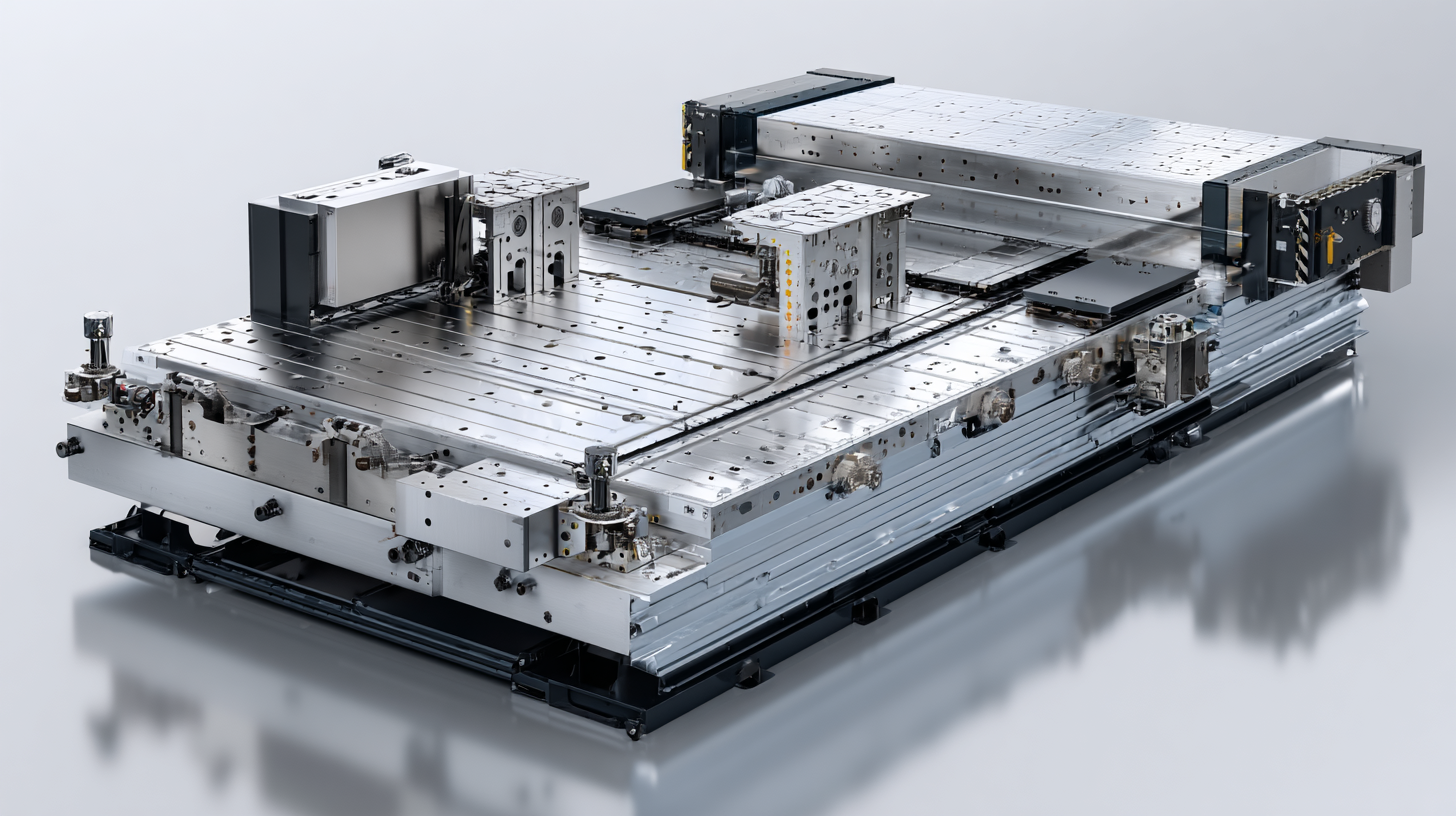

Top Features to Look for in Modern CNC Tables

When exploring the advancements in CNC tables for 2025, several key features stand out that prospective buyers should consider. First and foremost, precision and accuracy have reached new heights, thanks to the integration of advanced sensors and software. Modern CNC tables now boast closed-loop systems that ensure real-time feedback during machining processes, effectively minimizing errors and enhancing the quality of the final product. Additionally, improved spindle speed and torque capabilities allow for greater versatility in material handling, accommodating a wide range of applications from metal fabrication to intricate woodworking.

Another notable trend in CNC table technology is the shift towards user-friendly interfaces and automation. Many of the latest models are equipped with intuitive touchscreen controls and programmable options, making them accessible even for those with limited technical expertise. Moreover, automation features such as auto-tool changers and hardware-software integration streamline operations, saving valuable time and increasing productivity. With these advancements, modern CNC tables not only promise efficiency but also empower users to push the boundaries of their creative projects.

Essential Tips for Choosing the Right CNC Table for Your Needs

When selecting the right CNC table for your needs, it's essential to consider several critical factors. First and foremost, evaluate the size and workspace required for your projects. CNC tables come in various dimensions, and choosing one that fits your projects ensures efficiency and precision.

Additionally, consider the type of materials you will be working with—some tables are better suited for heavy materials like metal, while others excel with softer materials like wood and plastic.

Another vital aspect is the CNC table's capabilities and features. Look for advancements in technology, such as integrated software for easier programming or enhanced safety features. Upgraded models may offer faster processing speeds and higher accuracy, which can significantly boost productivity. Additionally, consider the table’s compatibility with existing machinery and tools, as this will influence how seamlessly you can integrate your new CNC table into your workflow. Taking the time to assess these considerations will help you find the CNC table that best aligns with your operational needs and aspirations.

Sustainability in CNC Technology: Eco-friendly Table Options

In recent years, sustainability has become a crucial consideration in manufacturing, and CNC technology is no exception. As businesses seek to minimize their environmental impact, eco-friendly CNC tables are emerging as a prime solution. These tables are being designed with sustainable materials and manufacturing processes that reduce waste and energy consumption. By utilizing recyclable substances and energy-efficient designs, manufacturers are not only catering to a growing demand for green solutions but also enhancing the durability and longevity of their products.

Moreover, advancements in CNC technology are enabling greater efficiency without compromising on performance. Innovations such as modular designs allow users to easily upgrade parts, further extending the lifespan of CNC tables. Additionally, the integration of smart technologies, like IoT sensors, helps monitor energy usage and optimize machining processes in real time. As industries shift toward sustainable practices, investing in eco-friendly CNC table options not only serves compliance with regulations but also contributes to a company’s corporate social responsibility profile, fostering a culture of sustainability within the manufacturing sector.

2025 Global Purchasing Guide to Best CNC Table Advancements and Trends - Sustainability in CNC Technology: Eco-friendly Table Options

| Feature | Description | Environmental Impact | Price Range (USD) |

|---|---|---|---|

| Recycled Materials | CNC tables made from recycled plastics and metals, reducing waste. | Lower carbon footprint due to use of recycled resources. | $500 - $2000 |

| Energy Efficiency | Tables designed for lower energy consumption during operation. | Significant reduction in energy usage leads to lower emissions. | $800 - $3000 |

| Modular Design | Easily adjustable and upgradable parts, reducing the need for a full replacement. | Less waste generated compared to traditional fixed designs. | $600 - $2500 |

| Smart Technology Integration | CNC tables equipped with IoT for monitoring and efficiency optimizations. | Improves resource usage and predictive maintenance, minimizing waste. | $1000 - $5000 |

| Biodegradable Components | Use of materials that break down naturally over time. | Minimizes long-term environmental impact through natural decomposition. | $500 - $2200 |